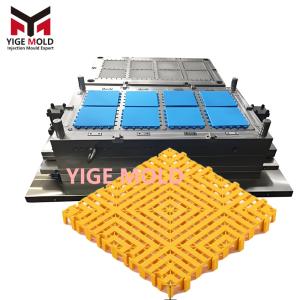

Custom Plastic Floor Tile Mold

Customized plastic floor tile molds are professional tools for creating personalized flooring systems. Yige Mold offers a full-process customized service from design to manufacturing in this field, dedicated to converting customers' unique functional requirements and design ideas into standard products that can be mass-produced.

The core of custom mold design lies in targeted design. We work closely with our clients, deeply understanding the specific requirements of the application scenarios - whether it's special anti-slip needs, specific load indicators, or unique patterns and dimensions. The engineers at Yige utilize their professional experience to convert these requirements into reasonable mold structures. Through optimized parting design and ejection schemes, they ensure the precise molding and smooth demolding of complex shapes and fine textures.

Manufacturing accuracy is the key to custom molds. Eiger uses high-precision processing equipment to finely process complex surfaces, ensuring the accurate reproduction of texture details. During the mold assembly stage, we strictly follow a step-by-step inspection process to guarantee the assembly accuracy of multiple component systems. Each set of custom molds undergoes a complete mold trial verification, is debugged to the optimal production state, and is then delivered.

Yigei Mold specializes in providing practical customized solutions. We focus on the reliability and production efficiency of molds, helping customers realize their design ideas while ensuring stable product quality and reasonable control of production costs. From theme spaces to professional venues, Yigei offers solid technical support for various personalized flooring projects with its professional customization capabilities.

The core of custom mold design lies in targeted design. We work closely with our clients, deeply understanding the specific requirements of the application scenarios - whether it's special anti-slip needs, specific load indicators, or unique patterns and dimensions. The engineers at Yige utilize their professional experience to convert these requirements into reasonable mold structures. Through optimized parting design and ejection schemes, they ensure the precise molding and smooth demolding of complex shapes and fine textures.

Manufacturing accuracy is the key to custom molds. Eiger uses high-precision processing equipment to finely process complex surfaces, ensuring the accurate reproduction of texture details. During the mold assembly stage, we strictly follow a step-by-step inspection process to guarantee the assembly accuracy of multiple component systems. Each set of custom molds undergoes a complete mold trial verification, is debugged to the optimal production state, and is then delivered.

Yigei Mold specializes in providing practical customized solutions. We focus on the reliability and production efficiency of molds, helping customers realize their design ideas while ensuring stable product quality and reasonable control of production costs. From theme spaces to professional venues, Yigei offers solid technical support for various personalized flooring projects with its professional customization capabilities.

Escriba su mensaje aquí y envíenoslo