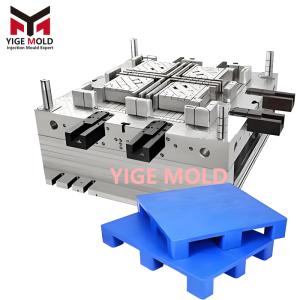

Industrial Plastic Floor Mold

The Industrial Plastic Floor Mold is a specialized field that combines precision mechanical processing with material engineering. Yige Mold has been deeply engaged in this field for many years and has established a complete manufacturing system from design to delivery. It focuses on providing customers with durable and stable mold products.

Mold manufacturing begins with raw materials. We select high-quality mold steel that has undergone pre-hardening treatment. Its hardness and toughness have been rigorously tested to ensure stable performance even under long-term high-load production. Through a five-axis联动 machining center, we achieve precise molding of complex cavities and reinforcement structures, with the accuracy of key mating surfaces controlled within ±0.05 millimeters. The internal thermal management system of the mold is scientifically designed, ensuring uniform heat conduction through multiple circulation channels to maintain dimensional stability.

Quality control during the manufacturing process is of utmost importance. We use a three-coordinate measuring device to verify the dimensions at each processing stage to ensure the mating accuracy of each component. After the molds are assembled, they undergo more than a thousand consecutive trial runs to verify their operational stability, and load tests are conducted to examine their long-term durability. Before each set of molds is delivered, a complete production parameter debugging is completed to ensure that users can quickly start production.

Yige Mold has always been committed to providing reliable professional tools for industrial flooring production through solid manufacturing techniques and strict quality control. We pay attention to the performance of the molds in actual use, helping customers achieve stable product quality and continuous production efficiency, and creating value in various industrial scenarios.

Mold manufacturing begins with raw materials. We select high-quality mold steel that has undergone pre-hardening treatment. Its hardness and toughness have been rigorously tested to ensure stable performance even under long-term high-load production. Through a five-axis联动 machining center, we achieve precise molding of complex cavities and reinforcement structures, with the accuracy of key mating surfaces controlled within ±0.05 millimeters. The internal thermal management system of the mold is scientifically designed, ensuring uniform heat conduction through multiple circulation channels to maintain dimensional stability.

Quality control during the manufacturing process is of utmost importance. We use a three-coordinate measuring device to verify the dimensions at each processing stage to ensure the mating accuracy of each component. After the molds are assembled, they undergo more than a thousand consecutive trial runs to verify their operational stability, and load tests are conducted to examine their long-term durability. Before each set of molds is delivered, a complete production parameter debugging is completed to ensure that users can quickly start production.

Yige Mold has always been committed to providing reliable professional tools for industrial flooring production through solid manufacturing techniques and strict quality control. We pay attention to the performance of the molds in actual use, helping customers achieve stable product quality and continuous production efficiency, and creating value in various industrial scenarios.

Escriba su mensaje aquí y envíenoslo