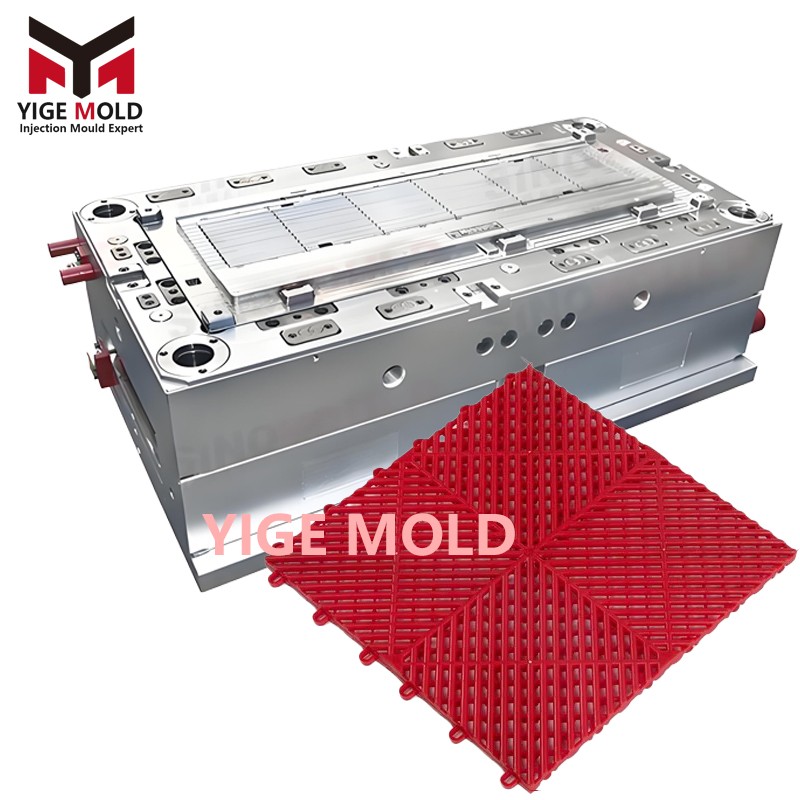

Car Wash Grid Mold

In an efficiently operated car wash, every insignificant groove grille plays an indispensable role. It not only quickly channels the surging water away, but also endures the daily crushing of several tons of vehicles silently. Behind this is the engineering practice of Yige Mold, which transforms the three key principles of "durability, efficiency, and safety" into the product's genetic code through precise manufacturing.

Precision is the starting point for the realization of functions.

At Yige, mold design begins with a deep analysis of the working conditions. We use fluid simulation to precisely plan every drainage path of the mold cavity, ensuring no stagnant water and high efficiency. Anti-slip is not a simple rough surface; instead, it is the friction coefficient precisely calculated through mold texture, which can provide reliable anti-slip performance in both dry and wet conditions. The mold body is made of high-grade alloy steel and undergoes rigorous heat treatment processes, ensuring that it maintains its initial accuracy throughout tens of thousands or even hundreds of thousands of molding cycles, fundamentally eliminating product deformation and size deviations.

Professional craftsmanship, empowering diverse scenarios

Yige is dedicated to providing customers with the most adaptable solutions:

• Professional injection molds: Optimized for high-performance engineering plastics such as polypropylene (PP). The cooling channels and ejection systems of the molds have been meticulously calculated to achieve a fast and stable production rhythm. The grilles produced have excellent chemical corrosion resistance and high toughness, making them an ideal choice for standard car wash stations.

Eagle Value: Beyond Tools, Providing Long-Term Certainty

Yige Mold provides much more than just a production tool. It is a predictable and stable quality output system. Choosing Yige means you are opting for lower long-term overall costs - reduced replacement expenses due to the durability of the product, decreased maintenance frequency due to efficient drainage, and avoidance of potential risks due to safety and reliability. We understand that every opening and closing of the mold defines the reliability and lifespan of the washroom floor facilities.

Precision is the starting point for the realization of functions.

At Yige, mold design begins with a deep analysis of the working conditions. We use fluid simulation to precisely plan every drainage path of the mold cavity, ensuring no stagnant water and high efficiency. Anti-slip is not a simple rough surface; instead, it is the friction coefficient precisely calculated through mold texture, which can provide reliable anti-slip performance in both dry and wet conditions. The mold body is made of high-grade alloy steel and undergoes rigorous heat treatment processes, ensuring that it maintains its initial accuracy throughout tens of thousands or even hundreds of thousands of molding cycles, fundamentally eliminating product deformation and size deviations.

Professional craftsmanship, empowering diverse scenarios

Yige is dedicated to providing customers with the most adaptable solutions:

• Professional injection molds: Optimized for high-performance engineering plastics such as polypropylene (PP). The cooling channels and ejection systems of the molds have been meticulously calculated to achieve a fast and stable production rhythm. The grilles produced have excellent chemical corrosion resistance and high toughness, making them an ideal choice for standard car wash stations.

Eagle Value: Beyond Tools, Providing Long-Term Certainty

Yige Mold provides much more than just a production tool. It is a predictable and stable quality output system. Choosing Yige means you are opting for lower long-term overall costs - reduced replacement expenses due to the durability of the product, decreased maintenance frequency due to efficient drainage, and avoidance of potential risks due to safety and reliability. We understand that every opening and closing of the mold defines the reliability and lifespan of the washroom floor facilities.

Escriba su mensaje aquí y envíenoslo