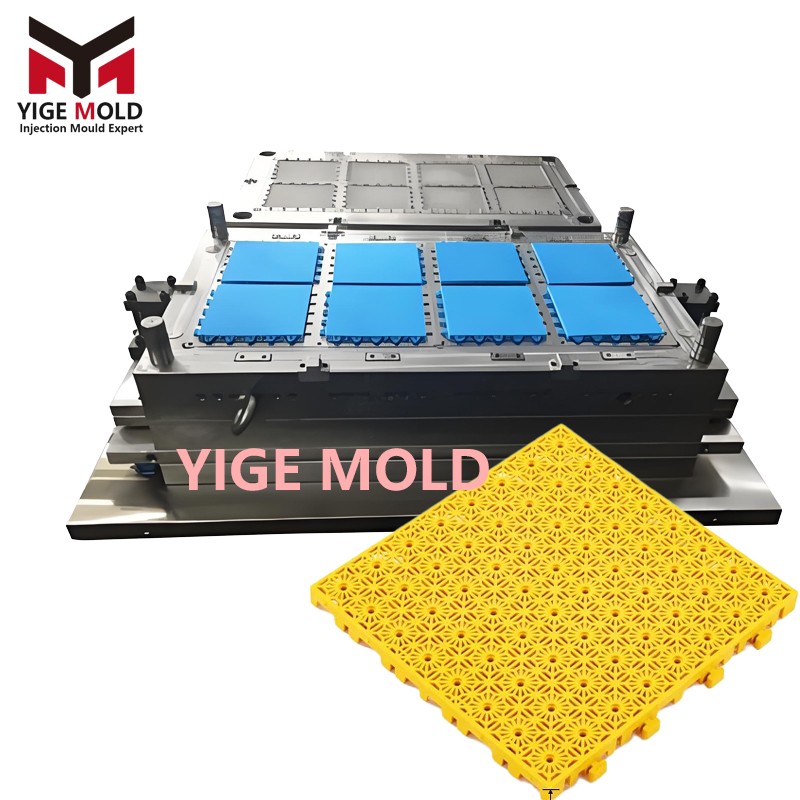

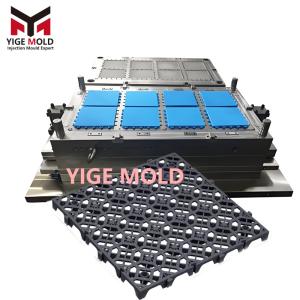

Plastic Grid Mold

The Plastic Grid Mold is the key to achieving high performance for grille products. Yige Mold starts with systematic engineering design, and through scientific structural definition, precise process control, and rigorous manufacturing execution, it transforms the molds into the core guarantee of performance and efficiency.

Mold design begins with rigorous requirements engineering. Through mechanical topology optimization and fluid simulation analysis, we define the optimal material distribution of the grid rib structure to meet the requirements of load-bearing and drainage performance, achieving a unified balance of lightweight and high strength. Regarding the molding quality, the flow channel system undergoes rheological design to ensure a balanced plastic flow front, precisely controlling the filling and cooling processes, in order to eliminate the deformation and internal stress problems commonly found in large grids. At the same time, the innovative modularized multi-functional cavity design enables a single mold to adapt to the stable production of various engineering plastics.

Precision manufacturing is the reliable realization of the design drawings. We employ five-axis联动 precision machine tools and online measurement technology to ensure the machining accuracy and finish of the core forming surfaces. The key mating mechanisms undergo multiple processes of grinding to ensure smooth movement and long-term durability. The material selection strictly uses certified high-quality mold steel, combined with precise heat treatment, making the molds both wear-resistant and tough. Each set of molds must complete systematic assembly calibration and continuous trial runs of up to ten thousand times before delivery, and their performance and stability are fully verified before delivery.

By integrating the design and manufacturing processes, Yige Mold has achieved precise prediction of product performance, stable and efficient production processes, and significant extension of the overall service life. We view the mold as a precise engineering system. With in-depth engineering design capabilities and strict manufacturing standards, we provide reliable, efficient, and durable plastic grille manufacturing solutions for customers in various industries.

Escriba su mensaje aquí y envíenoslo