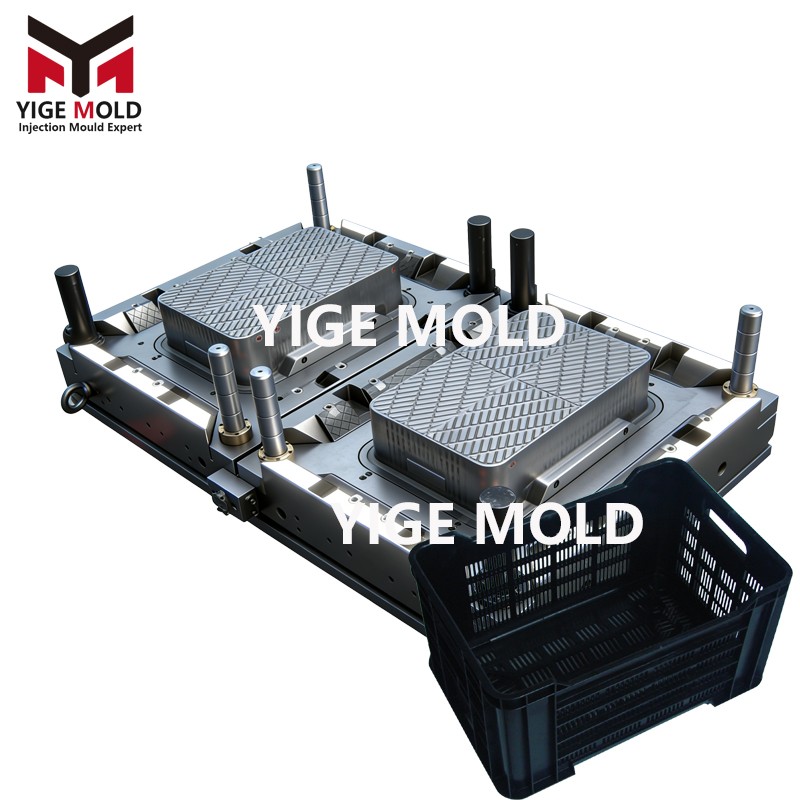

Fruit turnover box mold

Fruit pallet injection molds are core forming equipment specifically developed for the storage and transportation of fruits and vegetables. Among them, Yige molds, with their precise design and efficient processes, provide stable support for the mass production of pallets and have become a top choice in the industry. Yige molds are made of high-quality P20, 718H and other mold steel materials, which undergo multiple rigorous heat treatments such as quenching and nitriding. They have high hardness and strong wear resistance, can withstand long-term high-frequency injection molding operations, and have a service life of over 500,000 mold cycles, far exceeding the industry average in terms of durability.

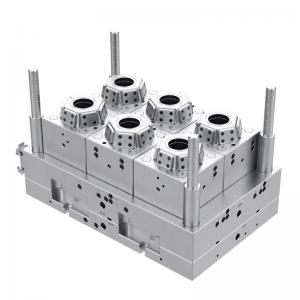

In terms of structural design, Yige molds are deeply tailored to the practical needs of fruit pallets, optimizing the cavity layout to achieve 1-4 cavity synchronous molding. This increases production efficiency by 30% compared to traditional molds, enabling enterprises to quickly respond to market demands. The molds are equipped with a precise temperature control system independently developed and debugged by Yige molds, ensuring uniform temperature differences in the pallets, avoiding wall thickness deviations, and allowing the produced pallets to have a load capacity of 15-30kg, with strong impact resistance and no easy deformation, capable of handling complex environments during fruit and vegetable transportation. Additionally, Yige molds adopt a combined ejection structure of pins and top plates, ensuring smooth demolding without scratches, maintaining a smooth surface and rounded corners of the pallets without burrs, effectively preventing damage to fruits and vegetables and safeguarding product quality.

To meet the core demand of fruit preservation, Yige molds support custom functional structures such as ventilation holes, anti-slip patterns, and stacking slots, balancing ventilation and stacking stability to help extend the preservation period of fruits and vegetables. Moreover, Yige molds are compatible with environmentally friendly materials such as PP and HDPE for injection molding, with a short molding cycle of 25-40 seconds. The molds are compact in size, easy to operate, and can be adapted to mainstream injection molding machines, significantly reducing production costs for enterprises.