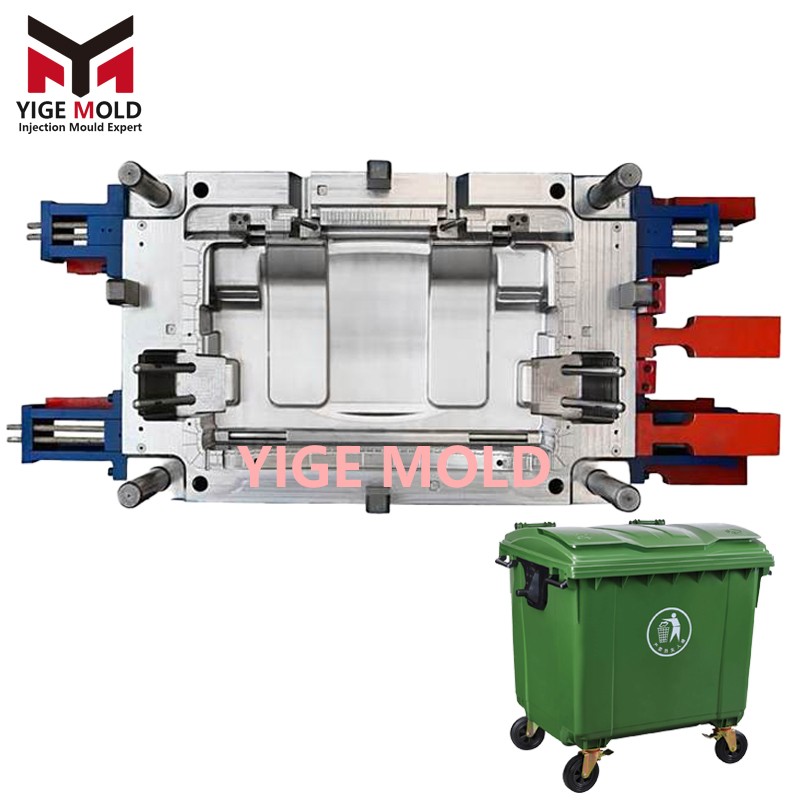

240L Industrial Plastic Garbage Bin Injection Mold

The 240L industrial trash can mold of Yige Mold is a professional injection mold specifically designed for manufacturing industrial-grade trash cans with a capacity of 240 liters. The main body of the mold is made of high-quality mold steel (such as P20, 718H), and the cavity precision can be controlled within ±0.03mm, ensuring that the product has a stable structure and no deformation or cracking after molding. The mold design adopts a hot runner system combined with a balanced gate, suitable for HDPE and other engineering plastics, allowing for uniform filling of the molten plastic and enabling one-time molding of complex structures such as the trash can body, lid, and foot pedal components.

The mold ejection system uses a combination of push rods and sliders. Special ejection schemes have been designed for the reinforced ribs of the trash can body, the slot for the foot pedal connecting rod, and other inverted structures to ensure that the product is ejected without any scratches or jams. The molded industrial trash cans have excellent impact resistance and aging resistance, and can pass outdoor wear and corrosion tests, suitable for a wide temperature range of -30°C to 60°C.

Supports multi-specification customization (such as 240L, 300L, 500L, etc.), and can integrate personalized designs such as classification identification slots, foot pedal connecting rods, and moving roller positions to meet the industrial-grade usage requirements of factories, parks, and environmental sanitation scenarios. Yige Mold strictly adheres to the ISO9001 quality system standard in mold manufacturing, with a mold lifespan of over 300,000 mold cycles and a regular production cycle of approximately 60 days.

As a comprehensive supplier in the field of mold manufacturing and molding solutions, Yige Mold is dedicated to providing customers with high-precision and long-lasting mold products and technical support.