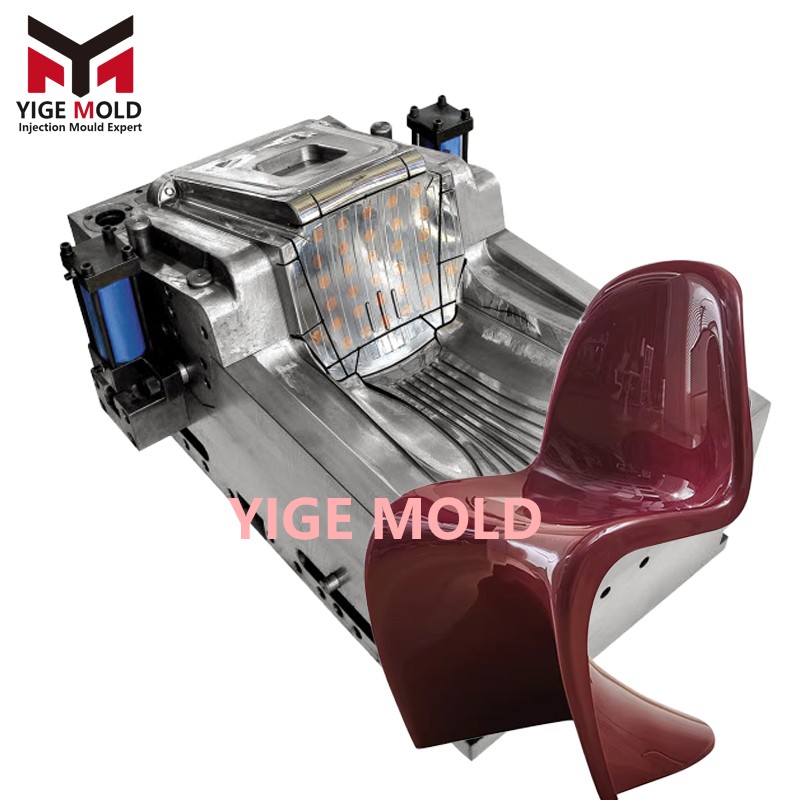

Garden Chair Mold

Garden chair molds are specialized injection tools used for mass-producing outdoor leisure chairs. The core lies in using precise mold technology to form plastic (such as PP, PE) into chairs that are structurally robust and weather-resistant in a single process. These molds are typically complex in design, taking into account ergonomic curves, load-bearing structures, as well as functional details like anti-slip and quick drainage.

With the market's increasing demand for aesthetics and personalization, molds with surface textures such as rattan and wood grain have become mainstream. Mold manufacturers endow plastic chairs with the visual beauty of natural materials by performing high-precision etching or engraving on the cavity surface.

In this specialized field, manufacturers with strong technical capabilities stand out. For instance, the well-known Yige Mould is dedicated to providing high-demand appearance part mould solutions. With its profound technical accumulation, Yige Mould can efficiently address common challenges in garden chair moulds, such as texture replication, large mould venting, and complex ejection structures, ensuring that the produced chairs are not only durable and comfortable but also have an exquisite and realistic appearance, helping brand customers establish a competitive edge in the outdoor furniture market.

In conclusion, the garden chair mold is a technological achievement that integrates industrial design, materials science and precision manufacturing. Its level directly determines the market competitiveness of the final product.

With the market's increasing demand for aesthetics and personalization, molds with surface textures such as rattan and wood grain have become mainstream. Mold manufacturers endow plastic chairs with the visual beauty of natural materials by performing high-precision etching or engraving on the cavity surface.

In this specialized field, manufacturers with strong technical capabilities stand out. For instance, the well-known Yige Mould is dedicated to providing high-demand appearance part mould solutions. With its profound technical accumulation, Yige Mould can efficiently address common challenges in garden chair moulds, such as texture replication, large mould venting, and complex ejection structures, ensuring that the produced chairs are not only durable and comfortable but also have an exquisite and realistic appearance, helping brand customers establish a competitive edge in the outdoor furniture market.

In conclusion, the garden chair mold is a technological achievement that integrates industrial design, materials science and precision manufacturing. Its level directly determines the market competitiveness of the final product.

Escriba su mensaje aquí y envíenoslo