Industrial Garbage Bin Mould

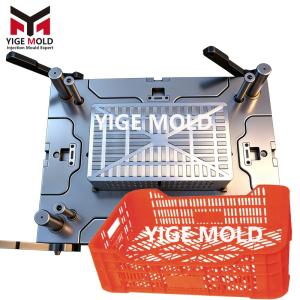

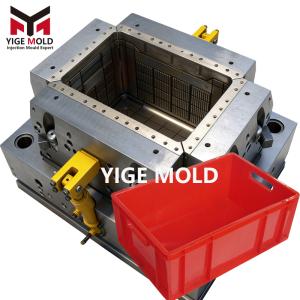

Yige industrial trash can injection molds are the core forming equipment for large-scale production of industrial trash cans. With the technical advantages of high precision and high stability, they have become a key support in the field of environmental protection equipment manufacturing. To meet the core requirements of industrial trash cans, such as large capacity, strong load-bearing capacity, impact resistance, and acid and alkali resistance, Yige molds use high-quality mold steels likeP20 and 718H as the base material. They are processed by precision equipment such as CNC machining centers and EDM spark machines, with a precision of ±0.01mm, perfectly meeting the forming requirements of different specifications of products.

The structural design of Yige molds takes into account both practicality and efficiency. They support single-cavity or 2-8 cavity custom layouts, and the optimized main runner and runner system ensure that molten plastic fills the cavities quickly and evenly. For complex structures such as deep cavities in the bucket body and inverted bucket lids, professional core-pulling mechanisms and ejection systems are equipped to achieve one-time molding, significantly reducing subsequent processing. The conformal cooling system, with evenly distributed water channels, rapidly cools down, compressing the molding cycle to 30-60 seconds per mold, and significantly improving production efficiency.

Yige molds have wide process compatibility and are compatible with engineering plastics such as PP, PE, and HDPE. Through parameter adjustments, they can produce trash cans with thicknesses of 2-8mm and capacities of 50-240L, meeting the needs of various scenarios such as factories, warehouses, and municipal sanitation. The mold surface is treated with nitriding and polishing, with a hardness of HRC50-55, excellent wear resistance and corrosion resistance, and a service life of 500,000 to 1 million mold cycles, effectively reducing long-term production costs.

In addition, Yige molds are equipped with precise guiding and positioning devices and safety protection mechanisms to ensure smooth and reliable opening and closing of the mold, reducing production failures. They also support personalized customization, allowing for the optimization of color, texture, and rib layout designs according to customer needs, providing efficient and reliable forming solutions for manufacturing enterprises and promoting the large-scale and standardized development of the environmental protection equipment industry.