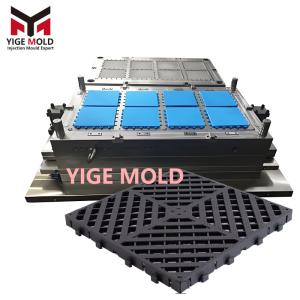

Plastic Floor Mold

As a professional manufacturer of plastic floor molds, Yige Molds focuses on providing high-precision and high-performance molding solutions for various paving systems. Through rigorous design and manufacturing processes, we ensure that each mold unit can meet the strict requirements of industrial paving.

The design of the Yige molds is based on the actual installation requirements. Through meticulous design of the snap-fit structure, reinforcement ribs layout and surface texture, we ensure that the floor modules can achieve precise interlocking and stable load-bearing. The key mating parts of the molds have a tolerance control within ±0.03mm, guaranteeing the flatness and joint quality of large-scale installation. The surface treatment adopts professional etching technology to ensure the long-term maintenance of anti-slip performance and decorative effect.

During the manufacturing process, Yige uses high-quality wear-resistant steel and employs five-axis precision machining to ensure the accuracy of the cavity. Each set of molds undergoes strict heat treatment processes to enhance their durability and dimensional stability. The design of the cooling system and exhaust channels has been optimized to achieve efficient production and stable forming quality.

Yige Mold attaches great importance to practicality and reliability. Our mold design takes production reality into full consideration, ensuring that customers can achieve efficient and stable mass production. From interior decoration to public places, Yige Mold, with its precise manufacturing process and professional technical support, provides customers with durable and long-lasting paving system solutions.

The design of the Yige molds is based on the actual installation requirements. Through meticulous design of the snap-fit structure, reinforcement ribs layout and surface texture, we ensure that the floor modules can achieve precise interlocking and stable load-bearing. The key mating parts of the molds have a tolerance control within ±0.03mm, guaranteeing the flatness and joint quality of large-scale installation. The surface treatment adopts professional etching technology to ensure the long-term maintenance of anti-slip performance and decorative effect.

During the manufacturing process, Yige uses high-quality wear-resistant steel and employs five-axis precision machining to ensure the accuracy of the cavity. Each set of molds undergoes strict heat treatment processes to enhance their durability and dimensional stability. The design of the cooling system and exhaust channels has been optimized to achieve efficient production and stable forming quality.

Yige Mold attaches great importance to practicality and reliability. Our mold design takes production reality into full consideration, ensuring that customers can achieve efficient and stable mass production. From interior decoration to public places, Yige Mold, with its precise manufacturing process and professional technical support, provides customers with durable and long-lasting paving system solutions.

Escriba su mensaje aquí y envíenoslo