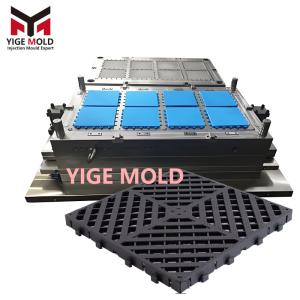

Car Floor Mat Mold

In the industrialized production of car floor mats, specialized molds are the core guarantee for achieving precise product adaptation and stable quality. Yige Mold has accumulated rich experience and technical capabilities through long-term practice, providing reliable manufacturing tools for the large-scale and high-quality production of automotive floor mats.

The key to the design of vehicle floor mats lies in achieving precise reproduction of the three-dimensional shape. The mold must accurately replicate the complex undulating contours, fixed points, baffle slots and threshold arcs of the floor of a specific vehicle model. Eiger Mold has established systematic operation standards in aspects such as surface data processing, precise cavity machining and assembly and debugging, ensuring that the finished mold can stably produce products that closely fit the vehicle chassis during injection or compression molding, effectively preventing displacement or warping during use.

In response to the common material compatibility challenges in foot pad production, such as the control of thick-wall shrinkage of TPE/rubber, and the bonding strength between the coil base material and the surface layer, Yige Mold has addressed these issues through professional design of the flow channel and cooling system, as well as special surface treatment processes. The molds of Yige Mold can maintain stable molding accuracy and surface quality during long-term use, meeting the strict requirements of the original equipment manufacturers for product consistency.

The key to the design of vehicle floor mats lies in achieving precise reproduction of the three-dimensional shape. The mold must accurately replicate the complex undulating contours, fixed points, baffle slots and threshold arcs of the floor of a specific vehicle model. Eiger Mold has established systematic operation standards in aspects such as surface data processing, precise cavity machining and assembly and debugging, ensuring that the finished mold can stably produce products that closely fit the vehicle chassis during injection or compression molding, effectively preventing displacement or warping during use.

In response to the common material compatibility challenges in foot pad production, such as the control of thick-wall shrinkage of TPE/rubber, and the bonding strength between the coil base material and the surface layer, Yige Mold has addressed these issues through professional design of the flow channel and cooling system, as well as special surface treatment processes. The molds of Yige Mold can maintain stable molding accuracy and surface quality during long-term use, meeting the strict requirements of the original equipment manufacturers for product consistency.

Escriba su mensaje aquí y envíenoslo