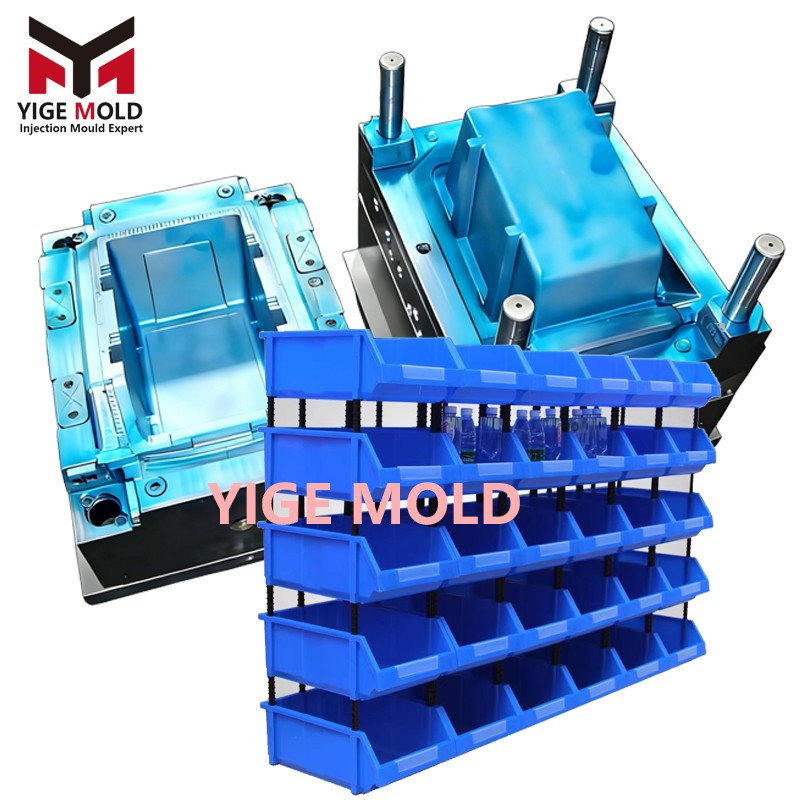

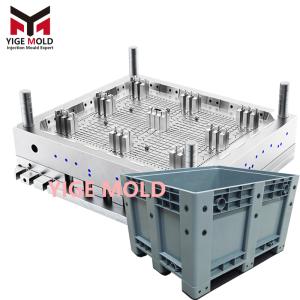

Parts Box Mold

Breve descripción:

Taizhou-made Parts Box Mold | YIGE MOLD delivers 500k+ injection cycles, anti-wear design, perfect for mass-producing plastic parts containers. 24/7 tech support! ...

- Mould Name: Parts Box Mold

- Mould Main Material: 718H;P20

- Mould Cavity: 1Cavity

- Delivery Time: 40 working days

Detalles del producto

Etiquetas del producto

YIGE MOLD’s Parts Box Mold is engineered for high-efficiency production of plastic parts storage boxes, tailored to industrial, automotive, and electronic component storage needs. Crafted with premium mold steel and precision machining (±0.01mm accuracy), this mold delivers consistent, burr-free parts boxes with every injection cycle. Backed by Taizhou’s mold industry expertise, we offer flexible customization to match your exact size, grid partition, and load-bearing requirements.

Core Advantages

-

Unmatched Precision & ConsistencyOur mold’s high-precision cavity and core design eliminates flash and dimensional deviations, ensuring uniform part box sizes that stack seamlessly. This reduces post-production trimming work and boosts product yield by 15% compared to standard molds.

-

Durable Material & Long Service LifeMade from high-grade alloy steel, the Parts Box Mold resists wear and corrosion, supporting 500,000+ injection cycles under standard working conditions. It is compatible with common engineering plastics (ABS, PP, HDPE, PC) to meet diverse storage demands.

-

Tailored Customization OptionsWe offer full structural customization: adjustable grid partitions for classified component storage, reinforced edge designs for heavy-load use, and surface texture options (matte, anti-slip, glossy). Multi-cavity choices (1–8 cavities) are available to match your production capacity.

-

Efficient Production OptimizationThe optimized runner and cooling system cuts injection cycle time by 10–20%, minimizing material waste and lowering unit production costs. Fast prototyping (7–10 days) allows you to verify product design before mass production.

Why Choose YIGE MOLD?

- Origin Strength: Based in Taizhou, the “Mold Capital of China”, we leverage local supply chain resources to offer competitive pricing and fast delivery (25–35 days for standard molds).

- Quality Assurance: Every mold passes strict dimensional testing and trial molding verification, complying with ISO 9001 quality standards.

- Global After-Sales Support: We provide 24/7 technical guidance, on-site maintenance support, and mold repair services for clients worldwide.

- Industry Expertise: With years of experience in storage box mold manufacturing, we understand the unique needs of automotive and electronic parts storage scenarios.

Application Scenarios

Our Parts Box Mold is ideal for producing:

- Industrial workshop component storage boxes

- Automotive spare parts organizing boxes

- Electronic device parts sorting containers

- Hardware tool small parts storage cases

Etiquetas:

Parts Box Mold

Escriba su mensaje aquí y envíenoslo