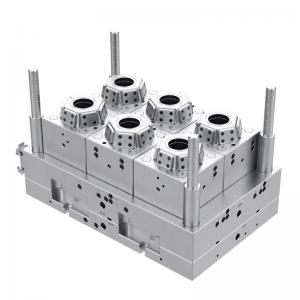

Four-compartment seasoning box mold

Injection mold manufacturing process for seasoning box

Mold structure design

Yige Mold adopts an integrated frame structure in the design of the seasoning box injection mold, consisting of a fixed mold and a moving mold. Considering the unique multi-grid separation feature of the seasoning box, Yige Mold innovatively designs a modular movable insert system. Each partition adopts a standardized assembly structure, which not only ensures processing accuracy but also significantly improves maintenance convenience. The mold is equipped with Yige's patented slider core-release mechanism, effectively solving the forming problems of the latch and sealing structure of the seasoning box.

Processing and manufacturing process

Yige Mold uses a five-axis联动 machining center to complete the high-precision processing of the mold frame and the cavity. The accuracy of key parts is controlled within ±0.01mm. In the electrical discharge machining process, Yige uses its independently developed electrode optimization scheme, significantly improving the production efficiency of the partition parts of the seasoning box. The mold surface undergoes multiple-level polishing treatment to ensure that the product meets food-grade surface requirements.

Assembly and debugging

Yige Mold strictly follows the modular pre-installation standard during the assembly stage, and all moving parts undergo running tests. The cooling system adopts Yige's patented spiral water channel design, with a heat exchange efficiency increase of over 30%. During the trial mold process, Yige engineers use the digital injection molding analysis system to precisely optimize the pouring parameters to ensure the balance of filling in the multi-grid cavities.

Quality control system

Yige Mold has established a full-process quality traceability system, enabling traceability from raw material entry to mold delivery. Key dimensions use online detection technology to monitor processing accuracy in real time. The mold must pass continuous operation tests before delivery to ensure production stability.

Mold structure design

Yige Mold adopts an integrated frame structure in the design of the seasoning box injection mold, consisting of a fixed mold and a moving mold. Considering the unique multi-grid separation feature of the seasoning box, Yige Mold innovatively designs a modular movable insert system. Each partition adopts a standardized assembly structure, which not only ensures processing accuracy but also significantly improves maintenance convenience. The mold is equipped with Yige's patented slider core-release mechanism, effectively solving the forming problems of the latch and sealing structure of the seasoning box.

Processing and manufacturing process

Yige Mold uses a five-axis联动 machining center to complete the high-precision processing of the mold frame and the cavity. The accuracy of key parts is controlled within ±0.01mm. In the electrical discharge machining process, Yige uses its independently developed electrode optimization scheme, significantly improving the production efficiency of the partition parts of the seasoning box. The mold surface undergoes multiple-level polishing treatment to ensure that the product meets food-grade surface requirements.

Assembly and debugging

Yige Mold strictly follows the modular pre-installation standard during the assembly stage, and all moving parts undergo running tests. The cooling system adopts Yige's patented spiral water channel design, with a heat exchange efficiency increase of over 30%. During the trial mold process, Yige engineers use the digital injection molding analysis system to precisely optimize the pouring parameters to ensure the balance of filling in the multi-grid cavities.

Quality control system

Yige Mold has established a full-process quality traceability system, enabling traceability from raw material entry to mold delivery. Key dimensions use online detection technology to monitor processing accuracy in real time. The mold must pass continuous operation tests before delivery to ensure production stability.

Write your message here and send it to us