Lounge chair injection mold

The injection mold for the reclining chair is the core equipment for mass production of plastic reclining chairs. Yige Mold has been deeply involved in this field and is a key support that helps enterprises achieve large-scale production.

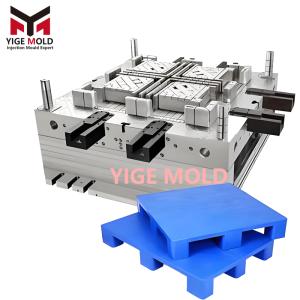

Yige Mold adopts a modular design, allowing for customization of product dimensions and appearance according to the customer's production capacity requirements. In terms of material selection, the mold frame uses high-quality S50C carbon steel, and the cavities and cores are preferably made of P20 or H13 wear-resistant mold steel. After professional quenching and nitriding treatment, the hardness reaches HRC45-50, featuring excellent wear resistance and corrosion resistance. The mold service life is stable and exceeds 500,000 mold cycles, reducing the long-term production costs for customers.

To further enhance production efficiency, Yige Mold integrates an efficient cooling system in the structure. Through simulation optimization of the flow path and cooling water layout, the plastic melt is quickly filled and uniformly cooled, reducing the molding cycle to 30-60 seconds per mold. At the same time, it is equipped with high-precision guiding and positioning mechanisms and a stable ejection system, ensuring smooth product demolding, effectively reducing defects such as burrs and shrinkage lines, and achieving a product size accuracy of ±0.05mm, precisely restoring the ergonomic arc of the reclining chair, and enhancing the product's comfort.

Yige Mold's reclining chair injection molds are compatible with common injection molding raw materials such as PP, PE, and ABS, and support integrated or split molding processes. They can also be customized with anti-slip textures, ventilation holes, and other personalized designs according to customer requirements, providing comprehensive solutions for different scenarios of reclining chair production, and offering reliable guarantees for enterprises to reduce costs and improve quality. It is the preferred equipment in the modern plastic reclining chair production field.