Translucent Basin Mold

Overview: When Aesthetic Art Meets Precision Manufacturing

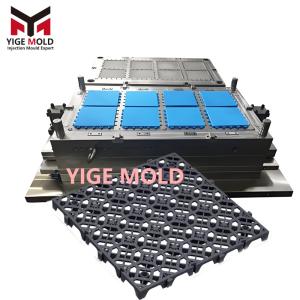

In today's global design landscape where translucent bathroom products are immensely popular, a successful translucent basin requires not only cutting-edge aesthetic design but also the sophisticated mold behind it. As a professional manufacturer with twenty years of expertise in the bathroom mold field, Yige Mold will provide an in-depth analysis of the entire technical process of translucent basin molds, from conceptual design to precision forming, showcasing how we transform artistic concepts into industrial realities ready for mass production.

Part 1: Professional Design – Laying the Aesthetic Foundation with Scientific Calculation

1.1 Synergistic Design of Optics and Structure

In translucent basin mold design, optical effects and structural strength must achieve perfect balance. Our engineering team utilizes advanced 3D modeling software combined with optical simulation technology to precisely calculate the wall thickness distribution across various sections of the product. Through the scientific design of gradient wall thickness structures, we ensure light achieves the ideal diffused effect within PC or acrylic materials, avoiding visual flaws such as localized over-brightness or darkness, truly delivering the sophisticated "uniformly translucent" quality.

1.2 Mold Flow Analysis to Predict Production Risks

Before machining begins, we employ professional MoldFlow analysis software for full-process simulation:

Filling Analysis: Predicts the flow path of plastic melt within the cavity, optimizing gate location and quantity.

Packing Analysis: Determines optimal packing pressure and time curves to minimize product shrinkage and warpage.

Cooling Analysis: Simulates mold temperature field distribution to optimize cooling channel layout.

Warpage Analysis: Anticipates product deformation trends early, allowing for compensation corrections at the design stage.

This "simulate first, manufacture later" digital development process resolves up to 90% of potential issues traditionally encountered during the drawing phase, significantly increasing development success rates.

1.3 Detail Design Tailored for Translucency

Venting System: Designed with multi-level venting structures (including parting line vents, insert vents, and dedicated vent pins) to address the material's sensitivity to trapped gas, ensuring complete air evacuation from the cavity and preventing burn marks or bubbles.

Cooling System: Utilizes 3D conformal cooling technology, maintaining a constant distance between cooling channels and product surfaces, controlling mold temperature uniformity within ±2°C—a critical factor for ensuring optical consistency in translucent products.

Ejection System: Combines pneumatic-assisted ejection and flat ejector pin designs to ensure smooth demolding of deep-cavity, thin-walled translucent basins, avoiding defects like ejector pin marks or stress whitening.

Part 2: Precision Manufacturing – Achieving Micron-Level Quality with Millimeter-Level Accuracy

2.1 High-Precision Cavity Machining

Yige Mold possesses a complete cluster of precision machining equipment, ensuring every mold meets the highest standards:

5-Axis Machining Centers: Complete precision milling of complex surfaces and irregular shapes in one setup, achieving machining accuracy of ±0.005mm.

Precision EDM (Electrical Discharge Machining): Machines deep cavities, narrow slots, and other areas inaccessible to milling cutters, achieving surface roughness down to Ra0.2μm.

Slow Wire EDM: Produces high-precision inserts and irregular holes with accuracy of ±0.003mm and perpendicularity ≤0.01mm/100mm.

2.2 Optical-Grade Surface Finishing Process

Surface finishing is the core process determining the translucent effect. We implement a standardized, traceable polishing workflow:

Process Stage

Materials Used

Target Roughness

Quality Control Points

Rough Polishing

Diamond Files, Oil Stones

Ra 0.4μm

Remove machining marks

Medium Polishing

Sandpaper (#800-#2000)

Ra 0.1μm

Uniform surface texture

Fine Polishing

Diamond Paste (3μm-0.5μm)

Ra ≤0.025μm

Achieve mirror finish

Final Inspection

3D Scanner, Roughness Tester

Full-dimensional inspection

Verify light transmission uniformity

All polishing operations are conducted in a Class 10,000 cleanroom, with dedicated QC inspection after each step, ensuring the final surface quality fully meets optical requirements.

2.3 System Integration and Trial Run Validation

After mold assembly is complete, we perform trial runs and validation on our in-house injection molding machines (280-2000 ton):

First Trial (T1): Validates basic mold functionality and product dimensions.

Process Optimization: Adjusts injection parameters, optimizes temperature, pressure, and speed profiles.

Small-Batch Pilot Run: Produces 50-100 consecutive parts to verify mold stability.

Final Acceptance: Customer on-site confirmation, providing a complete trial run report and process parameter sheet.

Part 3: Yige Mold Advantages – Why Top Global Brands Choose Us

3.1 Technical Accumulation and Innovation Capability

Patent Technology: Holds 12 national patents related to optical molds.

Material Database: Accumulated process parameters for over 200 types of engineering plastics.

Rapid Response: Standard mold design cycle of 15 days, 30% faster than industry average.

3.2 Quality Assurance System

Dual Inspection: Implements self-inspection + specialized inspection for each critical component.

Full Traceability: Every process, from steel stock intake to mold shipment, has a unique identification code.

International Certifications: Certified under ISO9001:2015 and IATF16949 quality management systems.

3.3 Success Case Data

Cumulative export of over 500 sets of translucent bathroom molds to European and American markets.

Average mold lifespan exceeds 1 million cycles.

Average customer product defect rate reduced to below 0.3%.

Part 4: Service Process – Full Support from Concept to Mass Production

4.1 Project Initiation Phase (1-3 days)

Requirement analysis meeting

Feasibility assessment

Project team formation

4.2 Design & Development Phase (15-20 days)

3D modeling & DFM analysis

Mold structure design review

Mold flow analysis & optimization

4.3 Mold Manufacturing Phase (30-45 days)

Precision machining & heat treatment

Assembly & debugging

Trial runs & optimization

4.4 Delivery & Support Phase (Ongoing Service)

Mold acceptance & training

Production process guidance

Lifetime maintenance support

Yige Mold Translucent Basin Mold: Perfect Integration of Professional Design and Precision Manufacturing

Yige Mold Translucent Basin Mold: Perfect Integration of Professional Design and Precision Manufacturing