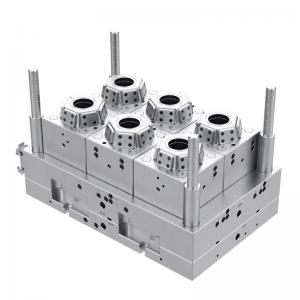

synthetic rattan furniture mold

Yige Mold, as a professional mold manufacturer, has been deeply engaged in the manufacturing of imitation rattan chair molds for many years. To meet the mass production requirements of rattan chairs, it has developed a series of high-precision and high-efficiency injection molding mold solutions.

I. Core Technical Advantages

Our molds are made from high-quality mold steel (such as P20, 718H or higher grades) through CNC precision machining and five-axis linkage engraving. They can perfectly replicate the natural texture, curves, and weaving details of handcrafted rattan. The mold design incorporates computer fluid dynamics analysis, optimizing the heat flow channels and cooling systems, ensuring that PP, PE, ABS and other engineering plastics achieve rapid and uniform filling and cooling during injection molding. This not only significantly enhances the production capacity and service life of each set of molds, but also fundamentally guarantees the dimensional stability, surface finish and mechanical strength of each finished chair leg, chair back or armrest component, making the mass-produced products both naturally beautiful and highly durable.

II. Product Performance Enhancement

The rattan chair components produced using Yige molds possess the following outstanding features:

• Realistic appearance: The detailed patterns etched by the molds give plastic products a visual effect that resembles genuine rattan weaving.

• Durability and Sturdiness: The product is highly resistant to impact and weathering, water-resistant and mold-proof, and does not crack or deform easily. It is especially suitable for outdoor use.

• Lightweighting and comfort: Achieve lightweight design while maintaining structural strength, and the ergonomic curve can be optimized through mold adjustment.

• Consistency and high efficiency: The mold production ensures zero-error consistency across product batches, significantly enhancing the production efficiency and quality control level of the furniture brand.

III. Customized Cooperation Model

We are well-versed in the diverse demands of the furniture market and offer a full-process service ranging from product design and analysis, mold design, prototype production to mass production maintenance. Whether it's the design of modern minimalist, retro classic or creative-shaped rattan chairs, EIG Mold can efficiently convert them into mature mold solutions that can be mass-produced, helping customers quickly respond to market trends and reduce overall production costs.

I. Core Technical Advantages

Our molds are made from high-quality mold steel (such as P20, 718H or higher grades) through CNC precision machining and five-axis linkage engraving. They can perfectly replicate the natural texture, curves, and weaving details of handcrafted rattan. The mold design incorporates computer fluid dynamics analysis, optimizing the heat flow channels and cooling systems, ensuring that PP, PE, ABS and other engineering plastics achieve rapid and uniform filling and cooling during injection molding. This not only significantly enhances the production capacity and service life of each set of molds, but also fundamentally guarantees the dimensional stability, surface finish and mechanical strength of each finished chair leg, chair back or armrest component, making the mass-produced products both naturally beautiful and highly durable.

II. Product Performance Enhancement

The rattan chair components produced using Yige molds possess the following outstanding features:

• Realistic appearance: The detailed patterns etched by the molds give plastic products a visual effect that resembles genuine rattan weaving.

• Durability and Sturdiness: The product is highly resistant to impact and weathering, water-resistant and mold-proof, and does not crack or deform easily. It is especially suitable for outdoor use.

• Lightweighting and comfort: Achieve lightweight design while maintaining structural strength, and the ergonomic curve can be optimized through mold adjustment.

• Consistency and high efficiency: The mold production ensures zero-error consistency across product batches, significantly enhancing the production efficiency and quality control level of the furniture brand.

III. Customized Cooperation Model

We are well-versed in the diverse demands of the furniture market and offer a full-process service ranging from product design and analysis, mold design, prototype production to mass production maintenance. Whether it's the design of modern minimalist, retro classic or creative-shaped rattan chairs, EIG Mold can efficiently convert them into mature mold solutions that can be mass-produced, helping customers quickly respond to market trends and reduce overall production costs.

Write your message here and send it to us