Plastic Stool Mold

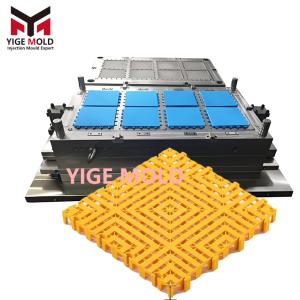

The plastic stool mold is not a single component, but a complex and precise system that transforms plastic particles into formed plastic stools. The core of it lies in the cavity design - a negative space that is precisely manufactured based on the three-dimensional data of the product. When the hot and molten plastic is injected into this cavity under high pressure, it determines the final shape, structural strength and surface texture of the stool.

Modern plastic chair molds are a combination of multiple engineering technologies. The interior of the mold is equipped with complex hot or cold flow channels to ensure that the plastic can fill the cavity uniformly and quickly; the cooling water circulation network is distributed around the cavity, precisely controlling the solidification process, which directly affects production efficiency and the dimensional stability of the products; the ejection system must smoothly push out the cooled and solidified chair without damaging it. For chairs that require folding or hinge functions, the mold also needs to be designed with a sophisticated lateral core-pulling mechanism.

The manufacturing materials and processes of Yige Mold are extremely meticulous. The main components are usually made of pre-hardened steel or quenched steel to ensure they can withstand the cyclic impact of high pressure and high temperature for a long time. The surfaces of key forming parts may undergo special treatments such as chrome plating or nitriding to enhance wear resistance, prevent corrosion and reduce the demolding resistance. From the initial 3D design to CNC machining, electrical discharge forming, precise grinding, and multiple rounds of mold testing and debugging, the entire process demonstrates high-precision manufacturing.

Modern plastic chair molds are a combination of multiple engineering technologies. The interior of the mold is equipped with complex hot or cold flow channels to ensure that the plastic can fill the cavity uniformly and quickly; the cooling water circulation network is distributed around the cavity, precisely controlling the solidification process, which directly affects production efficiency and the dimensional stability of the products; the ejection system must smoothly push out the cooled and solidified chair without damaging it. For chairs that require folding or hinge functions, the mold also needs to be designed with a sophisticated lateral core-pulling mechanism.

The manufacturing materials and processes of Yige Mold are extremely meticulous. The main components are usually made of pre-hardened steel or quenched steel to ensure they can withstand the cyclic impact of high pressure and high temperature for a long time. The surfaces of key forming parts may undergo special treatments such as chrome plating or nitriding to enhance wear resistance, prevent corrosion and reduce the demolding resistance. From the initial 3D design to CNC machining, electrical discharge forming, precise grinding, and multiple rounds of mold testing and debugging, the entire process demonstrates high-precision manufacturing.

Write your message here and send it to us