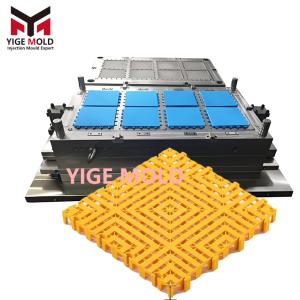

Plastic Face Wash Basin Mold

In the seemingly basic field of plastic basins, Yige Mold regards this product as a representative work that embodies industrial precision and scale reliability. Our mold solutions start from the systematic engineering implementation of "extreme durability" and "ultimate cost efficiency".

Core design philosophy: Designed for millions of cycles

• Integrated flow path and thermal management: The Yige Mold adopts a multi-loop conformal cooling system and optimized thermal flow channel design to ensure uniform filling and cooling of PP/PE materials in large thin-walled cavities. This not only shortens the injection molding cycle to the industry-leading level, but also fundamentally eliminates the warping deformation and internal stress of the basin body, ensuring the dimensional stability of the product in temperature difference environments.

• Structural topology based on mold flow analysis: We utilize advanced Moldflow simulation to precisely predict melt flow, joint positions, and cooling efficiency during the mold design stage. Based on this, we design a non-uniformly distributed reinforcement topology structure on the back of the basin, ensuring the same rigidity while optimizing material usage, thereby creating a direct cost advantage for our customers.

• Zero-defect ejection system: Considering the deep cavity and thin-walled characteristics of the basin, Yige Mold has developed a combined pneumatic and hydraulic auxiliary ejection system, which is combined with high-precision polishing or customized etching processes. This ensures smooth and seamless ejection every time, achieving a stable production yield rate of over 99.8%.

Precision Machining: From Digital Models to Reliable Tools

Yige Mold has a complete process chain ranging from heavy-duty CNC machining to precision electrical discharge machining and five-axis high-speed milling. We use pre-hardened high-quality mold steel and through precise machining, ensure the long-term wear resistance of the cavities. Particularly crucial is that we conduct non-destructive testing of the cooling water channels and white light interferometer testing of the polished surfaces to ensure that each set of molds meets the microscopic precision of the design specifications.

Conclusion

For Yige Mold, a set of toilet mold is not only a production tool, but also a commitment. Through cutting-edge engineering design and strict manufacturing standards, we incorporate the user values of "durability, reliability, and economy" into every detail of the mold, providing customers with full lifecycle value and market competitiveness that exceed expectations.