Round Household Trash Can Mold

A Custom Round Household Trash Can Mold is a precision-engineered tool specifically designed to manufacture cylindrical or rounded trash and recycling bins through the injection molding process. Unlike off-the-shelf solutions, a custom mold translates unique brand specifications—encompassing diameter, height, wall thickness, texture, and integrated features—into a mass-producible, high-quality product. This guide details the technical considerations, value propositions, and process behind creating a mold for a perfectly round household essential.

I. The Strategic Value of Custom Round Molds

Opting for a custom mold for round trash cans provides brands with critical competitive advantages that standard molds cannot offer:

-

Brand Identity & Product Differentiation: A custom mold allows for unique design signatures—specific profiles, patented rim designs, proprietary texturing, or branded embossing—that make your product instantly recognizable on the shelf or online.

-

Ergonomic & Functional Optimization: Dimensions can be tailored for specific use cases: a tall, slim bin for tight kitchen corners, a wide-diameter bin for high-volume disposal, or a perfectly sized bin to fit standard pre-made liners.

-

Cost-Effective at Scale: While requiring upfront investment, a custom mold eliminates per-unit licensing fees and provides complete control over the bill of materials. Over a production run of hundreds of thousands of units, it becomes the most economical solution, offering the lowest possible per-part cost.

-

Enhanced Structural Integrity: A custom-designed mold ensures optimal, uniform wall thickness throughout the cylindrical body. This prevents weak points, reduces material usage without sacrificing strength, and ensures consistent performance.

II. Key Engineering & Design Focus Areas

Designing a mold for a round part presents distinct challenges and opportunities that require specialized expertise:

-

Uniform Wall Thickness & Core-Centric Cooling: Achieving and maintaining consistent wall thickness around the entire circumference is paramount to prevent warpage and sink marks. This demands a perfectly centered mold core and a sophisticated conformal cooling system that follows the cylindrical geometry, ensuring even heat extraction for faster cycle times and dimensional stability.

-

Ejection Strategy for Deep-Draw Cylinders: Safely ejecting a deep, smooth-walled cylindrical part without distortion or surface scuffing is critical. A balanced system of ejector pins, sleeves, or a stripper plate must be carefully designed to apply even force around the part’s base or interior rim.

-

Gating for Cosmetic and Structural Integrity: Gate location is carefully chosen, often on the bottom center or a non-visible bottom edge, to:

-

Minimize Visible Flow Lines: Promote uniform, radial plastic flow to avoid weld lines on the visible side walls.

-

Ensure Structural Soundness: Direct material flow to maintain integrity, especially for bins with integrated handles or pedal mounts.

-

-

Integrated Feature Molding: The custom nature allows for the direct molding of complex features, eliminating secondary assembly:

-

Reinforced Bases: For stability and to prevent tipping.

-

Handle Cut-Outs or Grips: Molded directly into the bin wall.

-

Lid Attachment Points: Precise hinge sockets or grooves for snap-on lids.

-

Anti-Slip Rings or Feet: Textured or rubberized areas molded in place.

-

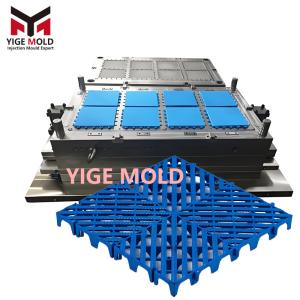

III. The Yige Mold Process: From Concept to Perfect Circles

At Yige Mold, we manage the entire journey of your custom round bin mold with precision and partnership:

-

Collaborative Design Feasibility: We analyze your 3D model for moldability, suggesting enhancements for draft angles, rib placement, and wall transitions to ensure flawless production.

-

Advanced Flow & Cooling Simulation: We utilize Moldflow analysis to simulate plastic flow, packing, and cooling within the cylindrical cavity. This virtual prototyping identifies and eliminates potential issues like air traps, uneven fill, or differential cooling long before steel is cut.

-

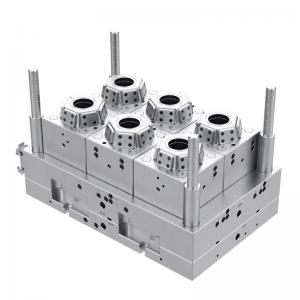

Precision Cylindrical Machining: Our 5-axis CNC machining centers and high-precision lathes are ideal for creating the perfect concentricity and surface finish required for the core and cavity of a round mold.

-

Comprehensive Validation & Sampling: The completed mold undergoes rigorous testing. We produce initial samples (T1 shots), measure for roundness, wall thickness, and consistency, and fine-tune the process. We provide you with approved samples and a complete Process Control Sheet detailing the optimized settings for mass production.

IV. Partnering with Yige Mold: Your Custom Solution Advantage

Choosing Yige Mold as your custom mold partner translates your vision into a manufacturing asset built for excellence:

-

Geometry-Specific Expertise: We have deep experience in the nuances of cylindrical part design, overcoming common pitfalls like ovality (out-of-round) and achieving perfect concentricity.

-

Efficiency-Built Design: Our focus on conformal cooling and balanced gating delivers industry-leading cycle times, reducing your cost per part over the mold’s entire lifespan.

-

End-to-End Ownership: We are your single point of accountability, from initial DFM feedback to final production validation and ongoing technical support.

-

Quality That Builds Your Brand: A mold from Yige Mold produces bins with consistent dimensions, flawless finish, and reliable performance—protecting your brand reputation with every unit shipped.