PVC Drainage Pipe Fitting Mold

Yige Mold provides a full range of pipe fitting molding solutions for PVC drainage systems. In response to the core requirements of PVC pipe fittings for low cost, high flow rate, and corrosion resistance, the mold design prioritizes high efficiency, long lifespan, and stability.

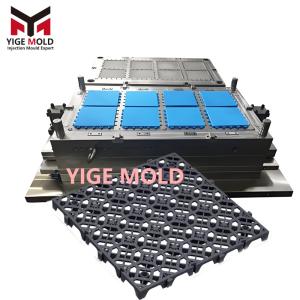

The mold adopts a highly standardized and modular design. By quickly replacing the core inserts, it can adapt to different specifications of three-way fittings, elbows, drain traps, etc., significantly enhancing production flexibility. The optimized cold runner and ejector layout ensures the quality of molding while simplifying the structure and reducing maintenance costs to the greatest extent.

Due to the poor thermal stability of PVC, the mold is equipped with a precise temperature control system to ensure rapid and uniform cooling, effectively shortening the molding cycle. The surface of the mold cavity is professionally treated to ensure smooth demolding and give the inner wall of the pipe fittings an appropriate roughness to optimize fluid performance.

Yige Mold, with an in-depth understanding of the processing characteristics of PVC materials, ensures that the mold has sufficient exhaust, stable pressure, and an extremely long service life and very low single-piece cost, providing reliable and economical equipment support for customers in the production of large-scale drainage pipe fittings in civil buildings, municipal engineering, and other fields.