Washing Machine Plastic Mold

Yige Electric Washing Machine Injection Mold: A Professional Solution for Large-Scale Precision Household Appliance Moldings

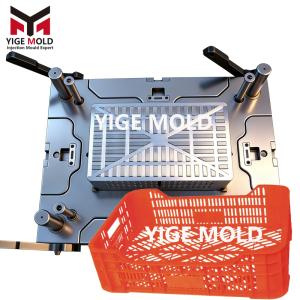

The injection mold for washing machines is a key equipment for manufacturing the core structural components of washing machines (such as the outer cylinder, inner drum, base, control panel, etc.). Yige Mold specializes in the professional manufacturing of this type of equipment. Through a precise hot runner system, large-sized high-strength mold frame design, and multi-loop conformal cooling technology, it effectively solves the industry problems such as size control, structural integrity, and production stability in the molding of large plastic parts.

Core technological innovation:

In the production of large-sized washing machine components (such as the outer cylinder and base), Egger Mould adopts its independently designed "partitioned sequential control pouring system". Through multi-point pressure sensing and intelligent compensation technology, the flatness tolerance is stably controlled within 0.3mm/m. For the densely reinforced ribs structure of the inner cylinder, Egger developed a "stepwise variable diameter exhaust scheme", completely solving the problem of insufficient filling caused by trapped air in the deep cavity structure.

Differentiated processing realization:

Based on the functional requirements of different components of the washing machine, Yige Mold provides differentiated surface treatment solutions: The exterior parts adopt mirror discharge processing to achieve a non-spraying texture; the structural parts use a special embossing process to enhance the plastic bonding strength. The molds are made of high thermal conductivity pre-hardened steel, combined with PVD coating technology, which not only improves wear resistance but also optimizes heat dissipation efficiency, ensuring that the mold life exceeds 800,000 mold cycles.

Production stability guarantee:

Yige Mold integrates a modular ejection system and an intelligent monitoring unit. It can monitor the mold temperature, pressure and ejection status in real time, enabling predictive maintenance. This design reduces the mold changeover time by 30% and increases the overall equipment utilization rate to over 85%.

As a key manufacturing support for the upgrading of the home appliance industry, Yige Mold has provided a large-scale and precise injection molding solution. This not only addressed the core production process challenges in washing machine manufacturing, but also offered customers a complete process stability guarantee from mold development to mass production. It helps home appliance products gain competitive advantages in terms of quality, efficiency and cost control.

The injection mold for washing machines is a key equipment for manufacturing the core structural components of washing machines (such as the outer cylinder, inner drum, base, control panel, etc.). Yige Mold specializes in the professional manufacturing of this type of equipment. Through a precise hot runner system, large-sized high-strength mold frame design, and multi-loop conformal cooling technology, it effectively solves the industry problems such as size control, structural integrity, and production stability in the molding of large plastic parts.

Core technological innovation:

In the production of large-sized washing machine components (such as the outer cylinder and base), Egger Mould adopts its independently designed "partitioned sequential control pouring system". Through multi-point pressure sensing and intelligent compensation technology, the flatness tolerance is stably controlled within 0.3mm/m. For the densely reinforced ribs structure of the inner cylinder, Egger developed a "stepwise variable diameter exhaust scheme", completely solving the problem of insufficient filling caused by trapped air in the deep cavity structure.

Differentiated processing realization:

Based on the functional requirements of different components of the washing machine, Yige Mold provides differentiated surface treatment solutions: The exterior parts adopt mirror discharge processing to achieve a non-spraying texture; the structural parts use a special embossing process to enhance the plastic bonding strength. The molds are made of high thermal conductivity pre-hardened steel, combined with PVD coating technology, which not only improves wear resistance but also optimizes heat dissipation efficiency, ensuring that the mold life exceeds 800,000 mold cycles.

Production stability guarantee:

Yige Mold integrates a modular ejection system and an intelligent monitoring unit. It can monitor the mold temperature, pressure and ejection status in real time, enabling predictive maintenance. This design reduces the mold changeover time by 30% and increases the overall equipment utilization rate to over 85%.

As a key manufacturing support for the upgrading of the home appliance industry, Yige Mold has provided a large-scale and precise injection molding solution. This not only addressed the core production process challenges in washing machine manufacturing, but also offered customers a complete process stability guarantee from mold development to mass production. It helps home appliance products gain competitive advantages in terms of quality, efficiency and cost control.

Write your message here and send it to us