Plastic Toolbox Mould

Short Description:

Cost-effective Plastic Toolbox Mould by Yige Mold – high durability with low maintenance costs. Optimized mold structure reduces material waste by 10%. Supports small to large batch orders, factory-direct pricing, and flexible payment terms for global buyers....

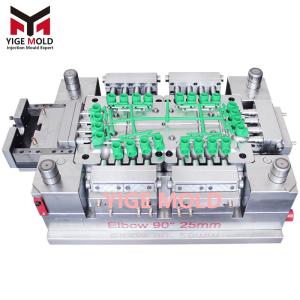

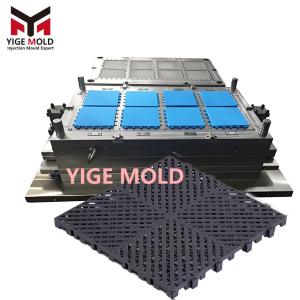

- Mould Name: Plastic Toolbox Mould

- Mould Main Material: 718H;P20

- Mould Cavity: 1Cavity

- Delivery Time: 40 working days

Product Details

Product Tags

Plastic Toolbox Mould | High-Precision Injection Molding Solutions by Yige Mold

H1: Plastic Toolbox Mould – Precision Engineered for Durable Tool Storage Production by Yige Mold

Core Product Overview

Core Advantages & Technical Highlights

Technical Specifications

Item

Details

Mould Precision

±0.1mm dimensional tolerance

Compatible Materials

PP, ABS, PC/ABS composite materials

Mould Lifespan

500,000+ molding cycles

Molding Cycle

15–30 seconds per unit (adjustable based on product size)

Customization Lead Time

7–15 days for rapid prototyping; 25–45 days for mass production moulds

Certification

ISO 9001, CE

Application Scenarios & Customer Value

Why Choose Yige Mold?