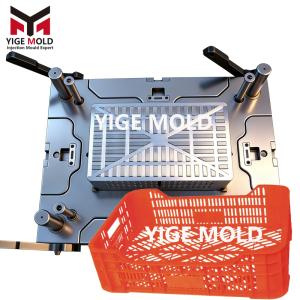

Toolbox Injection Mould

The Toolbox Injection Mould is a professional industrial mold solution developed and manufactured by Yige Mold. It is specifically designed for the production of various sizes of plastic toolboxes. This mold adopts a modular design concept and combines advanced injection molding technology, enabling efficient production of durable and structurally sound plastic toolboxes. It is widely used in areas such as tool storage, equipment transportation, and professional maintenance.

Core feature

Precise engineering structure

• Multi-chamber modular design: Supports configurations of 1×2, 1×4 or 2×4 chambers, flexibly adapting to various production requirements.

• Optimize the flow channel layout: Balanced hot runner system, ensuring uniform filling and reducing material waste

2. Yige Mold's Durable Material Configuration

• Core/cavity material: Utilize the P20 pre-hardened mold steel selected by Yige Mold or a higher-grade S136H stainless steel.

• Surface treatment: Special hardening treatment for Yige molds is carried out to HRC 48-52, followed by mirror polishing/etching process.

• Key Components: The wear-prone parts such as the pins and sliders are made of the standard SKD61 material from Yige Mold, which helps to extend their service life.

3. Intelligent Function Design

Yige Mold incorporates a built-in slider mechanism: enabling the one-time molding of complex features such as tool box handles and clasps.

• Automatic Thread Removal System: An exclusive patent technology of Yige Mold, suitable for the production of toolboxes with threaded sealing covers.

Yige Rapid Mold Change System: Equipped with standardized interfaces, the mold replacement time is reduced by 40%.

4. Efficient Production Optimization

• Cooling system optimization: Eiger Mold's 3D conformal cooling water channels, reducing the circulation time by 25%

• Exhaust system: Eiger Mold's multi-stage exhaust design, preventing burning and insufficient filling

Yige Mold Technical Specifications

Mold parameters

• Applicable injection molding machines: 180 - 450 ton clamping force

• Mold size: Customized design by Yige Mold. Typical dimensions range from 600×500×400mm to 800×600×500mm.

Total weight: 2.5 - 4.5 tons (varies according to specifications)

Yige Mold's expected service life: 800,000 to 1,200,000 cycles (under normal maintenance conditions)

Production parameters

• Material compatibility: PP, ABS, HDPE, modified engineering plastics, etc.

• Formation time: 40 - 60 seconds (depending on the product's wall thickness and size)

• Daily output: 1,200 - 1,800 pieces per set of molds (operating 24 hours)

Product specification compatibility

• Toolbox size range: from small (300×200×150mm) to large (600×400×300mm)

• Structural characteristics: Capable of producing various designs such as stacked, folded, and sealed types.

• Surface treatment: Offers various surface effects such as smooth finish, fine texture, and anti-slip particles.

Application fields

Professional tool manufacturer's matching toolbox

Automobile repair equipment storage box

Power and Telecommunication Maintenance Toolbox

Precision instrument transport case

Outdoor work equipment box

Customized tool storage solution

Yige Mold Quality Control

• Inspection standard: Compliant with ISO 9001:2015 quality management system. Yige Mold strictly adheres to it.

• Accuracy testing: Full-scale testing with the three-dimensional measuring instrument

• Document support: Provide complete 3D model files of the molds, Yigei mold maintenance manual and operation guide

Yige Mold Service Support

• Design Consultation: Yige Mold offers free product optimization and mold solution suggestions

• Delivery guarantee: Standard delivery period is 45-60 days. Yige Mold provides express service.

• Technical Training: On-site installation, commissioning, operation and maintenance training for Yige engineers

Yige's after-sales guarantee: 18-month warranty period and lifetime maintenance support

• Spare parts supply: Offer original Eiger brand wear parts and quick replacement services

Yige Mold Customization Service

We support fully customized development, which can be adjusted according to the specific needs of the customers:

• The configuration of cavities and the product layout

• Special structural design (such as reinforcing ribs, snap-fit mechanisms, etc.)

Brand logo and texture customization

Adapt to the special requirements of the automated production line

Yige Mold Value Advantage

1. High Efficiency: The optimized cooling and ejection system of Yige molds significantly enhance production efficiency.

2. High Quality: The precise processing of Yige molds ensures stable product dimensions and surface quality.

3. Long Life: The high-quality materials and reasonable design of Yige molds extend the service life of molds.

4. Low Maintenance: The modular design of Yige molds makes daily maintenance more convenient.

5. Flexible Production: Yige molds are adaptable to various materials and product variations, enhancing production flexibility.

Contact us to obtain exclusive quotations and technical solutions for Yige Mold.