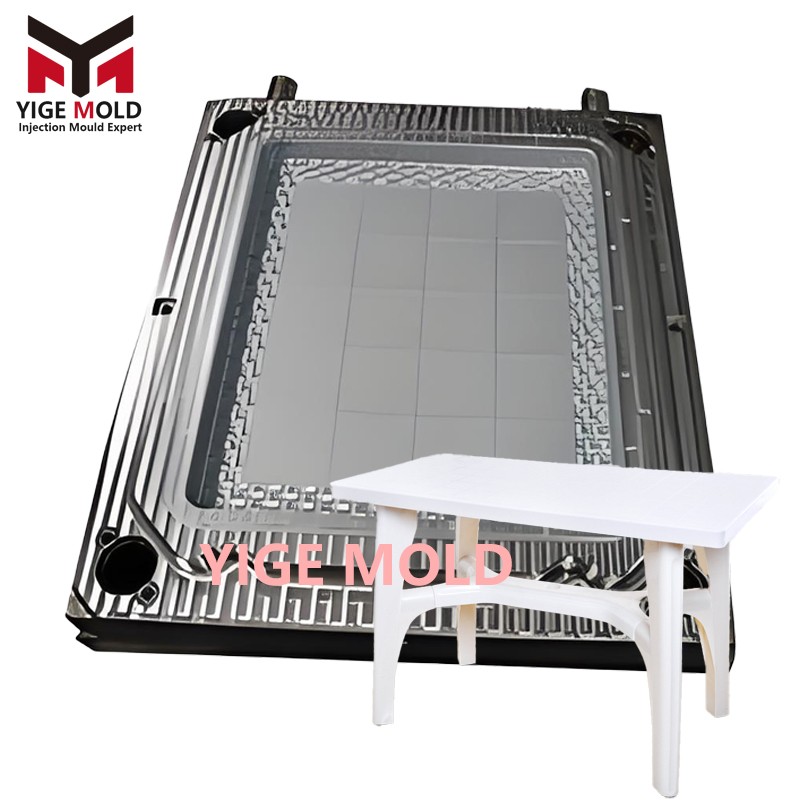

Plastic table mould

Plastic table mould are key process equipment for large-scale and high-efficiency production of plastic tables (such as outdoor tables, children's tables, and simple tables, etc.). Their core function is to inject molten plastic into precise cavities under high pressure, and after cooling and solidification, obtain table bodies with stable dimensions and complete structures.

Take the domestic professional Yige Mould as an example. The plastic table moulds it manufactures usually select high-quality mould steel (such as P20, 718, S136, etc.) and undergo precise processing and heat treatment to ensure the moulds have high hardness, high wear resistance and long service life. A typical mould system includes the cavity for forming the tabletop, the core for forming the table legs or support structure, as well as the crucial cooling water channels, ejection system and gate runner. Yige Mould pays attention to the balance of the runner and the uniformity of cooling in the design to shorten the forming cycle, reduce internal stress and ensure the product does not deform.

The standard working process is as follows: plastic pellets are plasticized and melted in an injection molding machine, then injected into a closed mold cavity under high pressure. After rapid solidification through circulating cooling water, the mold is opened and the finished product is automatically ejected by a pin or push plate. Yige molds are skilled at structurally designing to form table bodies with wood grain textures, reinforcing ribs or built-in inserts in one molding process. The products have good consistency and high production efficiency.

Therefore, injection molds produced by professional manufacturers like Yige Mould are the core for achieving low-cost, high-quality, and large-scale manufacturing of plastic tables. They not only determine the appearance and structure of the products but also directly affect production efficiency and market competitiveness. They are indispensable precision tools that connect product design with mass production.

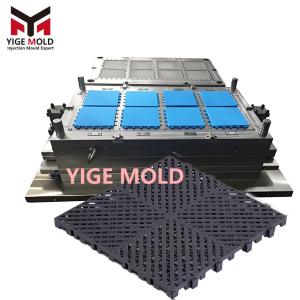

Take the domestic professional Yige Mould as an example. The plastic table moulds it manufactures usually select high-quality mould steel (such as P20, 718, S136, etc.) and undergo precise processing and heat treatment to ensure the moulds have high hardness, high wear resistance and long service life. A typical mould system includes the cavity for forming the tabletop, the core for forming the table legs or support structure, as well as the crucial cooling water channels, ejection system and gate runner. Yige Mould pays attention to the balance of the runner and the uniformity of cooling in the design to shorten the forming cycle, reduce internal stress and ensure the product does not deform.

The standard working process is as follows: plastic pellets are plasticized and melted in an injection molding machine, then injected into a closed mold cavity under high pressure. After rapid solidification through circulating cooling water, the mold is opened and the finished product is automatically ejected by a pin or push plate. Yige molds are skilled at structurally designing to form table bodies with wood grain textures, reinforcing ribs or built-in inserts in one molding process. The products have good consistency and high production efficiency.

Therefore, injection molds produced by professional manufacturers like Yige Mould are the core for achieving low-cost, high-quality, and large-scale manufacturing of plastic tables. They not only determine the appearance and structure of the products but also directly affect production efficiency and market competitiveness. They are indispensable precision tools that connect product design with mass production.

Write your message here and send it to us