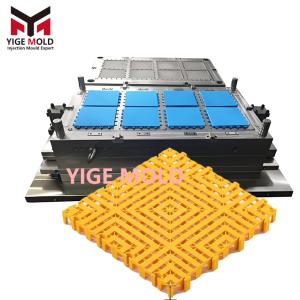

Milk Crate Mold

Short Description:

High-precision Milk Crate Mold for injection molding—durable P20/718H steel construction, 300k-1M shot life. Customizable for dairy, beverage & agriculture, with 25-30s cycle time and 99.5% accuracy. Eco-friendly, UV-stable & freezer-safe solutions....

- Mould Name: Milk Crate Mold

- Mould Main Material: 718H;P20

- Mould Cavity: 1Cavity

- Delivery Time: 40 working days

Product Details

Product Tags

Premium Milk Crate Mold from Yige Mold: High-Precision Injection Molding Solutions for Industrial Needs

When it comes to durable, high-efficiency plastic milk crate production, Yige Mold delivers industry-leading injection molding solutions tailored for dairy, beverage, agriculture, and logistics sectors. Our Milk Crate Mold is engineered with precision craftsmanship and cutting-edge technology, ensuring consistent, top-tier outputs that meet the rigorous demands of heavy-duty transportation and storage. Whether you need stackable dairy crates, fruit storage containers, or beverage transport boxes, Yige Mold offers fully customizable designs to match your exact performance and aesthetic requirements.

Core Advantages of Yige Mold’s Milk Crate Mold: Durability, Precision & Efficiency

- Superior Material Selection: Crafted by Yige Mold from high-grade P20/718H steel with 28–55 HRC hardness, this mold ensures an impressive 300,000–1,000,000 shot life, perfect for long-term, high-volume production. Corrosion-resistant and wear-proof, it maintains shape stability even under extreme molding conditions— a hallmark of Yige Mold’s commitment to quality.

- High-Precision Engineering: Yige Mold’s Milk Crate Mold boasts 99.5% dimensional accuracy, guaranteeing uniform crate sizes, smooth surfaces, and secure interlocking/stacking performance. Compatible with PP, ABS, HDPE, and recyclable plastic blends, it supports eco-friendly production aligning with Yige Mold’s sustainable manufacturing philosophy.

- Efficient Production Design: Featuring hot/cold runner options and optimized cavity structures by Yige Mold’s R&D team, this mold cuts cycle time to 25–30 seconds, boosting production efficiency significantly. Its innovative design minimizes material waste by up to 15%, reducing your operational costs while upholding Yige Mold’s standard of cost-effectiveness.

Customization Capabilities from Yige Mold for Diverse Needs

Yige Mold specializes in bespoke solutions to match your unique specifications:

- Size & Shape Customization: Yige Mold tailors crate dimensions (square, rectangular, folding) and cavity count (1–6 cavities) based on your sample or 3D drawings (STP, IGS, X-T formats accepted). Every modification reflects Yige Mold’s attention to detail and customer-centric approach.

- Functional Add-Ons: Yige Mold offers UV stabilizer integration for outdoor durability, freezer-safe modifications for cold-chain logistics, and hot-stamping features for branding or anti-theft markings. These customizations showcase Yige Mold’s versatility in meeting niche industry demands.

- Process Adaptation: Yige Mold’s Milk Crate Mold is compatible with standard injection molding machines, with personalized adjustments for clamping force and material flow. Our technical team ensures seamless integration into your production line— a testament to Yige Mold’s end-to-end support.

Reliable Manufacturing & After-Sales Support from Yige Mold

- Streamlined Production Timeline: Yige Mold guarantees a 50–70 day tooling lead time, with expedited options available for urgent orders. Each mold undergoes 3 rounds of strict quality inspection before shipment, ensuring zero defects— a promise from Yige Mold to its global clients.

- Comprehensive Technical Support: Yige Mold provides 2D/3D design files, on-site installation guidance, and 24-hour responsive after-sales service. Our team is always on hand to resolve operational issues, reinforcing Yige Mold’s reputation for reliable customer support.

- Industry-Proven Performance: Trusted by logistics, dairy, and agricultural manufacturers worldwide, Yige Mold’s Milk Crate Mold delivers consistent output, cost-saving benefits, and adaptability to diverse market demands. Choosing Yige Mold means partnering with a leader in injection mold manufacturing.

Wide-Ranging Applications of Yige Mold’s Milk Crate Mold

Ideal for producing crates for:

- Dairy Industry: Milk bottle transport, yogurt container storage, and cold-chain logistics (featuring Yige Mold’s freezer-safe design).

- Agriculture: Fruit, vegetable, and agricultural produce turnover and preservation.

- Beverage & Retail: Stackable transport for bottles, cans, and packaged goods, maximizing storage space with Yige Mold’s precision-engineered stacking structure.

- General Logistics: Heavy-duty storage boxes for industrial parts, tools, and consumer goods.

Tags:

Milk Crate Mold

Write your message here and send it to us