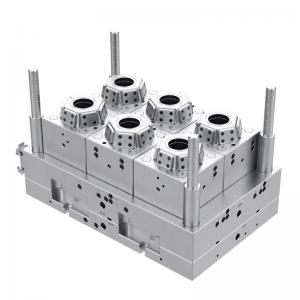

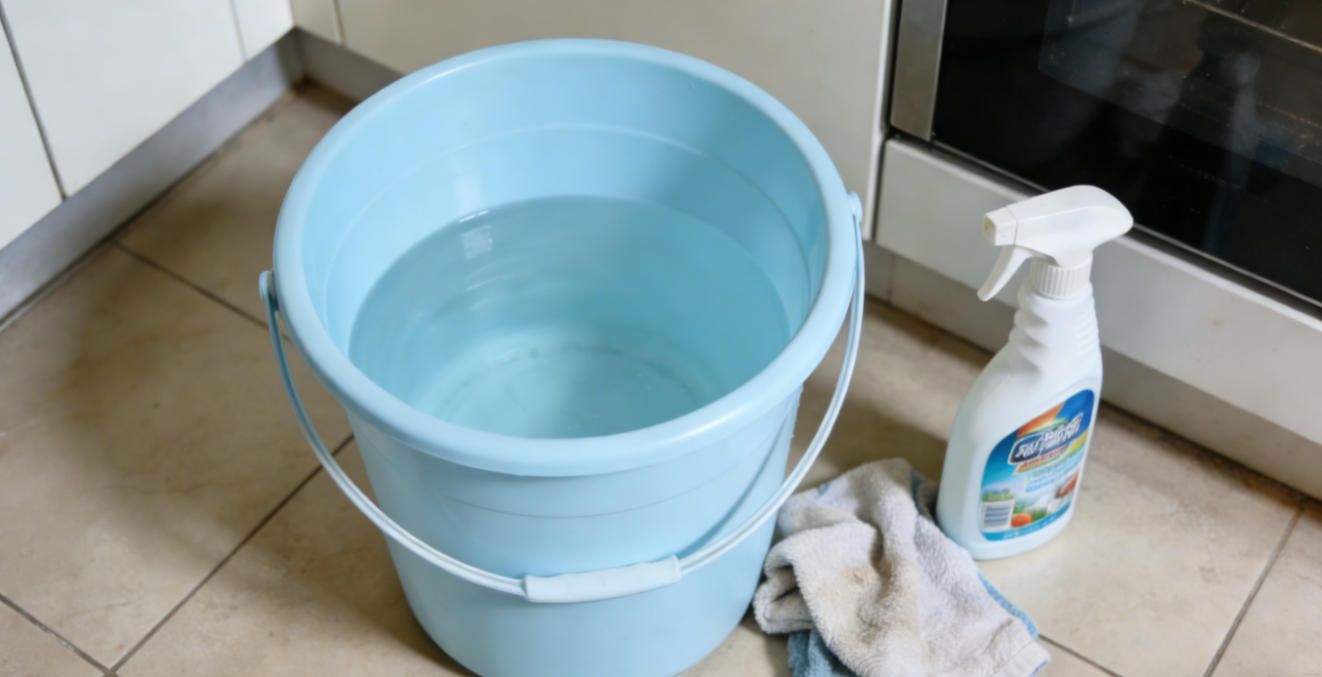

Plastic Water Pail Mold

The design of plastic water pail molds requires balancing functionality, practicality, and production efficiency. The pail body adopts a fully enclosed design, with the base featuring an anti-slip textured structure. The side walls incorporate 3-5 sets of annular reinforcing ribs to enhance structural stability. The handle employs ergonomic design and is integrally molded with the pail body, with a thickness-gradient transition structure at the connection points to increase mechanical strength.

Mold Dimension Specifications: Length 800-1200mm × Width 600-900mm × Height 400-700mm

Injection Molding Machine Requirements: Clamping Force 600-1200 tons

Molding Cycle Time: 45-75 seconds (depending on pail capacity)

Cooling Time Proportion: 55%-65%

Gate Design: 2-4 valve-gated hot runner injection points

The mold employs a three-dimensional, three-layer cooling structure:

Base Cooling Ring: Utilizes beryllium copper inserts with a thermal conductivity of 380 W/m·K for the thick-walled base area.

Mid-layer Spiral Water Channels: Arranged along the curved surface of the pail body, with water flow controlled at 25-35 L/min.

Upper-layer Localized Cooling: Independent cooling units are set in the handle and rim areas.

Pneumatic-Assisted Ejection Device: 6-8 pneumatic ejection points are set at the pail base.

Multi-Stage Ejection Mechanism: Utilizes a hybrid hydraulic + mechanical ejection system.

Separated Ejection Design: The pail body and handle employ different draft angles for demolding.

Pail Interior Cavity: Mirror polished to Ra ≤ 0.025μm.

External Texturing: Laser etching process with texture depth of 0.1-0.3mm.

Handle Area: Textured finish to enhance grip friction.

High-Density Polyethylene (HDPE): Melt Flow Index 2-4 g/10min.

Linear Low-Density Polyethylene (LLDPE): Used for products requiring high elasticity.

Food-Grade Materials: Compliant with FDA 21 CFR 177.1520 standards.

Melt Temperature: 210-230°C

Injection Pressure: 80-120 MPa

Packing Pressure: 60%-70% of injection pressure

Mold Temperature: 40-60°C

Pail Mouth Roundness Error: ≤ 0.15%

Wall Thickness Uniformity: ±5%

Handle Symmetry: ≤ 0.3mm

Volume Accuracy: ±2%

Drop Test: Free fall from 1.5-meter height, pail body remains intact without cracking.

Stacking Test: No deformation after 24 hours under full load stacked 3 layers high.

Handle Strength Test: Withstands 3 times the rated load without breakage.

Leakage Test: No water leakage after 24 hours of static filling.

Robotic Part Removal System: Equipped with visual positioning.

Online Trimming Device: Simultaneously removes flash and gates.

Automatic Stacking System: Palletizing neatness error ≤ 2mm.

Preventive Maintenance Cycle: Comprehensive maintenance every 100,000 cycles.

Wear Part Replacement Time: ≤ 2 hours.

Surface Repair Process: Laser cladding repair technology.

Servo Drive System: 40%-60% more energy-efficient than traditional hydraulic systems.

Heat Recovery Device: Cooling water waste heat recovery efficiency ≥ 30%.

Intelligent Temperature Control System: Energy consumption reduced by 15%-20%.

Runner Optimization Design: Material waste reduced by 25%.

Recycled Material Utilization: Allows addition of 20%-30% recycled material.

Sprue and Runner Recovery System: Online granulation for direct reuse.

Mold Base Steel: P20/718 pre-hardened steel.

Cavity Steel: S136/H13 heat-treated to HRC 48-52.

Moving Components: SKD61 with nitriding treatment.

Surface Coating: DLC coating hardness HV2500-3500.

Anti-Corrosion Treatment: Electroless nickel plating thickness 8-12μm.

Rust Prevention: VCI vapor corrosion inhibitor technology.

Interlock Device: Safety doors interlocked with injection molding machine.

Emergency Stop System: Multi-point emergency stop buttons.

Safety Limits: Dual protection with mechanical and electronic limit switches.

Operating Temperature: 15-35°C

Humidity Control: 40%-70% RH

Cleanliness Class: ISO Class 8

Operation Training: Standards for mold installation and commissioning.

Maintenance Training: Daily upkeep and troubleshooting.

Process Training: Parameter optimization and problem-solving.

Remote Diagnostics: 24/7 online support.

On-site Service: Arrival within 48 hours.

Spare Parts Supply: Common parts delivered within 72 hours.

Sensor Integration: Real-time monitoring of pressure, temperature, and position.

Data Acquisition: Automatic recording and analysis of production parameters.

Predictive Maintenance: Fault early warning based on big data analysis.

Antibacterial Materials: Addition of silver-ion antibacterial agents.

Anti-Aging Materials: UV stabilizer content 0.3%-0.5%.

Lightweight Materials: Microcellular foaming technology reduces weight by 10%-15%.

These technical specifications are continuously updated. All parameters are based on laboratory testing and production validation. Appropriate adjustments should be made according to specific conditions during actual application. It is recommended to evaluate mold performance quarterly to ensure stability in production efficiency and product quality.

Professional Manufacturing Technical Specifications for Plastic Water Pail Molds

Professional Manufacturing Technical Specifications for Plastic Water Pail Molds

Mold Design Philosophy and Technical Parameters

Structural Design Elements

Technical Parameter Standards

Core Technological Innovations

Layered Cooling System

Ejection System Optimization

Surface Treatment Processes

Material Adaptation Technology

Raw Material Selection Standards

Process Parameter Optimization

Quality Control System

Dimensional Accuracy Control

Performance Testing Standards

Production Efficiency Optimization

Automated Production Integration

Mold Maintenance Plan

Energy-Saving and Environmental Technologies

Energy Management Measures

Material Utilization Improvement

Mold Life Assurance

Material Selection Standards

Protective Measures

Safety Technical Specifications

Operational Safety Design

Production Environment Requirements

Technical Service Support

Training Service System

Technical Support Response

Innovation and Development Directions

Intelligent Upgrades

New Material Applications