Car Floor Mat Mold

Automotive Floor Mat Molds - Professional Manufacturing and Precision Design Solutions

Core Technologies in Mold Design and Manufacturing

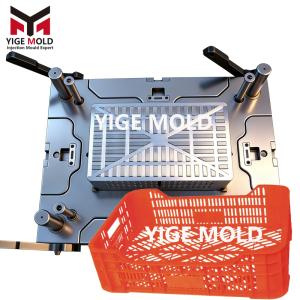

Automotive floor mat molds are critical tools in the production of automotive interior accessories. Yige Molds utilizes advanced CAD/CAM 3D design technology combined with Finite Element Analysis (FEA) for structural optimization, ensuring mold cavity precision reaches micrometer-level accuracy.

High-Precision Design Features

Molds are precision-machined using five-axis machining centers, with cavity accuracy controlled within ±0.02mm. Through optimized runner system design and the application of patented fan-shaped runner technology, balanced filling of molten plastic in multi-cavity molds is achieved, effectively eliminating weld lines and air pocket defects. The molds are equipped with optimized cooling channel designs combined with copper tube-aluminum fin heat exchangers, improving cooling efficiency by up to 30%.

Material Selection and Process Optimization

Premium mold steels such as P20, 718, and S136 are selected, undergoing heat treatment processes including tempering, quenching, and nitriding to achieve hardness levels up to HRC 35-38. The mold surface is treated with TiN coating technology, extending mold lifespan by 3-5 times. The molds support injection molding with various plastic materials, including PP, ABS, HDPE, PC, PVC, PA6, PA66, and PET.

Injection Molding vs. Thermoforming Process Comparison

Advantages of Injection Molding

Injection molding requires specialized injection molding machines and molds to ensure high-precision forming. Injection-molded floor mats require no secondary processing, are seamless, have smooth surfaces free of scratches, and feature clear surface text and patterns. Injection-molded floor mat products better ensure compatibility with vehicle models and achieve high fit precision.

Thermoforming Process Characteristics

Thermoforming molds have lower costs and are suitable for small-batch production. A single thermoforming mold can produce products with different materials and thicknesses, but may result in uneven thickness, dimensional instability, and require more post-processing.

Eco-Friendly Material Applications

The production of automotive floor mats incorporates recyclable and environmentally friendly materials. TPE materials meet medical-grade and food-grade environmental standards, offer safety and anti-slip properties, durability, and resistance to high and low temperatures. TPE automotive floor mats combine the advantages of PVC and rubber mats, being non-toxic, odorless, elastic, anti-slip, and anti-static.

Application Areas and Market Prospects

Automotive floor mat molds are widely used in car beauty shops, 4S stores, automotive repair shops, and other related fields. The products feature waterproof and anti-slip properties, wear resistance, durability, and environmental safety. With the rise of new energy vehicles, the automotive floor mat mold industry will encounter more development opportunities.

Reasons to Choose Yige Molds

-

Technical Expertise: A professional design team with over ten years of mold manufacturing experience

-

Quality Assurance: Every mold undergoes strict quality inspections and trial molding verification

-

After-Sales Service: Technical support and rapid response to solve various production issues

-

Competitive Pricing: Cost reduction through large-scale production, offering customers the most competitive prices

For more information about automotive floor mat molds or to request a customized solution, please feel free to contact us. We are committed to providing professional technical support and high-quality after-sales service.