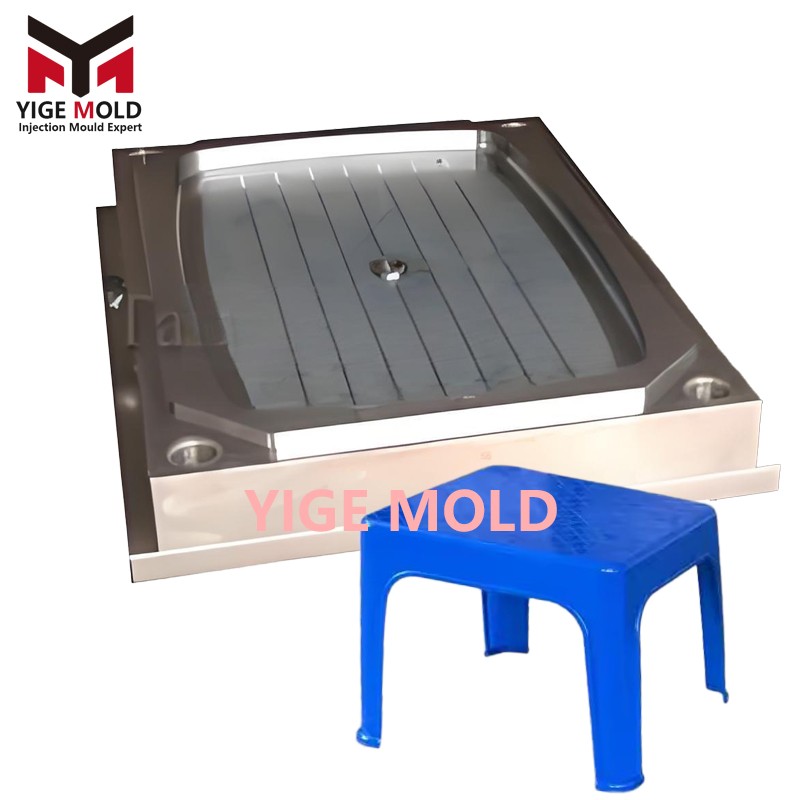

Injection mold for plastic tables

Injection mold for plastic tables is a specialized forming tool used for mass production of various plastic table bodies with high efficiency. Its core lies in melting the plastic at high temperature and injecting it into the precise mold cavity. After cooling and shaping, a structurally complex and dimensionally stable table component can be obtained at one time. It is the key manufacturing carrier for transforming products from drawings to physical objects.

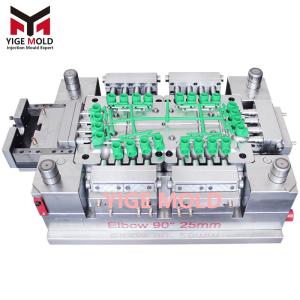

Take professional manufacturer Yige Mold as an example. The plastic table molds produced by them usually use high-quality mold steel and undergo precise CNC processing and heat treatment to ensure the high hardness, high wear resistance and long service life of the molds. A complete mold system includes the cavity for forming the tabletop, the core for constituting the supporting structure, as well as the cooling system, ejection system and flow channel system to ensure production efficiency and product quality.

In Eiger Mold's solution, the mold design and manufacturing are closely centered around product requirements and production efficiency. It optimizes the flow channel layout to reduce material waste and scientifically designs the cooling water channels to uniformly and rapidly lower the mold temperature, thereby significantly shortening the injection molding cycle and ensuring the consistency of product dimensions and the flatness of the surface. Ultimately, Eiger Mold not only provides a single mold, but also a complete technical solution that guarantees the high quality, low cost, and large-scale production of plastic table products.

Take professional manufacturer Yige Mold as an example. The plastic table molds produced by them usually use high-quality mold steel and undergo precise CNC processing and heat treatment to ensure the high hardness, high wear resistance and long service life of the molds. A complete mold system includes the cavity for forming the tabletop, the core for constituting the supporting structure, as well as the cooling system, ejection system and flow channel system to ensure production efficiency and product quality.

In Eiger Mold's solution, the mold design and manufacturing are closely centered around product requirements and production efficiency. It optimizes the flow channel layout to reduce material waste and scientifically designs the cooling water channels to uniformly and rapidly lower the mold temperature, thereby significantly shortening the injection molding cycle and ensuring the consistency of product dimensions and the flatness of the surface. Ultimately, Eiger Mold not only provides a single mold, but also a complete technical solution that guarantees the high quality, low cost, and large-scale production of plastic table products.

Write your message here and send it to us