Outdoor Table Mold

The outdoor table mold is a precision tooling specifically designed for manufacturing outdoor plastic tables. Its design standards are much higher than those of ordinary indoor table molds. It needs to focus on addressing challenges such as ultraviolet aging, temperature variations, rain erosion, and load-bearing strength in the harsh outdoor environment.

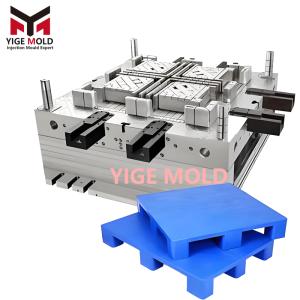

Professional outdoor table mold solutions, such as those provided by Yige Mold, take special considerations in terms of materials, structure and process. The mold steel needs to have higher corrosion resistance and strength to withstand the wear caused by long-term production. In the design, Yige Mold will focus on strengthening the product structure, such as increasing the thickness and reinforcement design of the table legs and support parts, and finely processing the surface texture to enhance the anti-slip performance and the high-end textures like wood imitation or stone imitation.

In addition, the cooling system of the mold needs to ensure that the material (usually PP or UV-resistant modified PE) can cure uniformly and rapidly, in order to reduce deformation and enhance the product's weather resistance. Through the integrated design and precise manufacturing of Yige molds, the outdoor table components produced not only have precise dimensions and smooth assembly, but also ensure that the final product has excellent environmental tolerance and long service life. This is the key guarantee for outdoor furniture manufacturers to achieve high-quality and large-scale production.

Professional outdoor table mold solutions, such as those provided by Yige Mold, take special considerations in terms of materials, structure and process. The mold steel needs to have higher corrosion resistance and strength to withstand the wear caused by long-term production. In the design, Yige Mold will focus on strengthening the product structure, such as increasing the thickness and reinforcement design of the table legs and support parts, and finely processing the surface texture to enhance the anti-slip performance and the high-end textures like wood imitation or stone imitation.

In addition, the cooling system of the mold needs to ensure that the material (usually PP or UV-resistant modified PE) can cure uniformly and rapidly, in order to reduce deformation and enhance the product's weather resistance. Through the integrated design and precise manufacturing of Yige molds, the outdoor table components produced not only have precise dimensions and smooth assembly, but also ensure that the final product has excellent environmental tolerance and long service life. This is the key guarantee for outdoor furniture manufacturers to achieve high-quality and large-scale production.

Write your message here and send it to us