Plastic Washbasin Mold

Plastic Washbasin Mold lies in transforming simple daily items into industrial products that can be mass-produced with high consistency. The core of its technology is the meticulous design and processing centered around "efficiency, stability, and durability".

Design oriented towards manufacturing

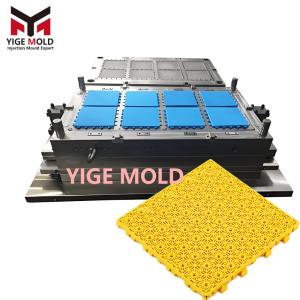

The primary goal of mold design is to serve efficient and stable production. The parting surface must ensure a perfect product appearance and smooth demolding; the multi-point hot runner system design ensures rapid and uniform filling of the melt, eliminating weld marks; and the conformal cooling waterway is the core for controlling the production cycle and preventing product deformation. In this field, Yige Mold, with a profound understanding of the rheological properties of materials such as polypropylene (PP), can precisely balance the filling efficiency and uniform cooling in its design, ensuring the stability of mass production from the very beginning.

2. Processing techniques for durability

Excellent design requires top-notch craftsmanship. The core of the mold cavity is made of high-hardness mold steel, which is precisely processed by CNC and polished to a mirror finish, ensuring a smooth and easy demolding process on the product surface. For products requiring anti-slip treatment, Yige Mold's expertise in fine etching (sunken lines) technology can give the basin body a consistent and durable matte texture. More importantly, the process control ensures the high wear resistance and long lifespan of the mold itself, thus guaranteeing that the product size and appearance remain stable even after millions of injections.

3. System Integration and Verification

The reliability of the molds is ultimately verified through the system. Eiger Mold applied mold flow analysis (CAE) for simulation optimization in the early stage of the project, and carried out precise debugging during the trial mold stage to ensure that the optimal process window was achieved from the first mold. This full-process technical loop from design, processing to verification makes the molds it manufactures not only production tools, but also a guarantee system for quality and efficiency.

Conclusion

A durable and user-friendly plastic basin, behind which lies the crystallization of precise mold engineering. Eiger Mold combines rigorous design, exquisite craftsmanship and systematic verification to infuse the core value of "reliability" into every set of molds and the millions of products they produce.