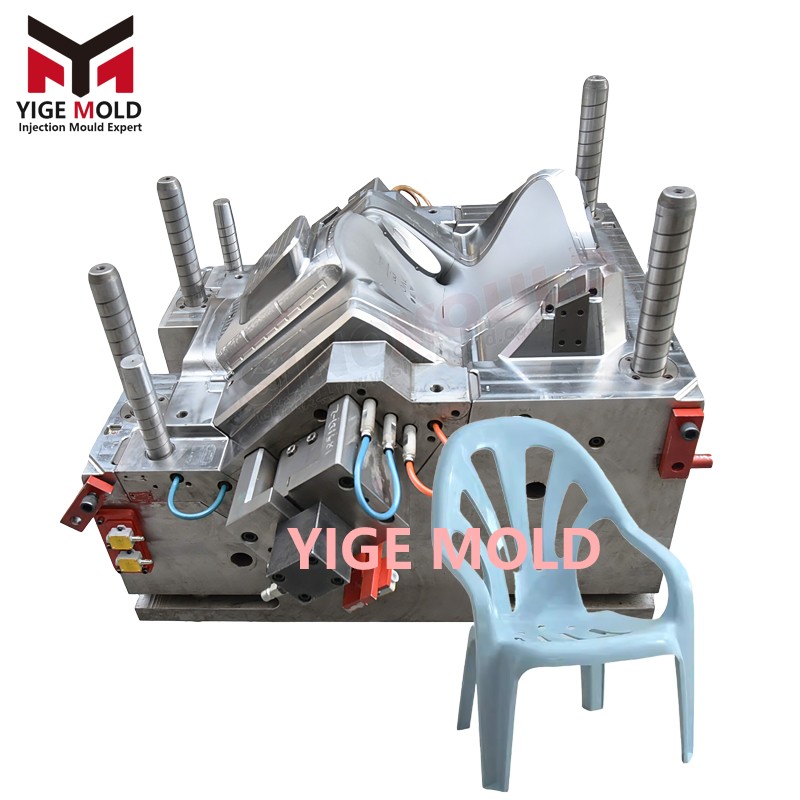

Interchangeable Insert Chair Mold

Interchangeable Insert Chair Mold: A Precision Engineering Revolution in Modular Manufacturing

Interchangeable Insert Chair Mold: A Precision Engineering Revolution in Modular Manufacturing

In the field of modern industrial manufacturing, efficiency, flexibility, and cost control are the core benchmarks for measuring technological advancement. For mass-market consumer goods like plastic chairs, which have huge demand and rapidly iterating styles, the traditional model of one mold producing only one product variant struggles to meet the market's need for small batches, high variety, and fast delivery. The Interchangeable Insert Chair Mold is a modular engineering solution born precisely to meet this challenge. It represents a significant shift in mold design from a "fixed" to a "flexible" paradigm. Its core value lies in maximizing the efficiency of the entire production system through localized replaceability.

I. Design Philosophy: A Modular Architecture of "Constancy Within Change"

The essence of interchangeable insert mold design is the ingenious engineering separation of the "fixed" from the "variable."

1. The Constancy of the Base Frame

The main mold structure—including the standard mold base, guiding system, gating system (often a hot runner), core cooling circuits, and ejection mechanism—is designed as a robust, stable, and universal "platform." This platform acts like a car's chassis, providing a unified foundation of power, support, and operation for all derivative models. It is engineered and manufactured to exceptionally high standards to ensure excellent rigidity and precision stability over millions of cycles, forming the fundamental guarantee for consistent product quality across all variants.

2. The Flexibility of Functional Inserts

The "variable" elements are encapsulated within meticulously designed independent inserts. These typically include:

-

Cavity/Core Inserts: Key components that determine the main shape, size, and dimensions of the chair. By swapping inserts of different sizes, chairs of varying widths, depths, or heights can be produced on the same mold platform.

-

Feature Inserts: Independent modules for forming localized chair features. The most common are backrest inserts and armrest inserts. By exchanging inserts with different shapes, textures (e.g., wood grain, leather grain), or镂空 patterns, stylistically diverse product families can be created without modifying the main mold body.

-

Functional Structure Inserts: Used to form specific snap-fit features, rib layouts, or connector interfaces. This allows the same base chair model to be adapted to different functional accessories.

This design confines the scope of mold modifications triggered by product changes from the entire mold to one or several standardized inserts, achieving an exponential reduction in changeover costs and a geometric increase in response speed.

II. Core Technology: Engineering Practices Ensuring Precision Interchangeability

Achieving rapid and precise interchangeability of inserts is non-trivial; it relies on a series of rigorous engineering practices.

1. Ultra-Precision Interface Design and Machining

The core of interchangeability lies in the interface. The locating interface between the insert and the mold base typically employs a composite system of high-precision taper locators, rectangular keys, and high-preload bolt groups. The taper locators ensure the insert returns to an exact, zero-play position in three-dimensional space, with repeatability better than ±0.005mm. All interface surfaces must be machined using ultra-high-precision CNC equipment under constant temperature conditions to guarantee absolute dimensional stability and interchangeability.

2. Integrated Yet Independent Subsystems

Each insert is a fully functional sub-unit:

-

Independent Cooling Circuit: Each insert integrates an optimized internal cooling channel network, connected to the main mold base circuit via high-efficiency quick-disconnect couplings. This ensures cooling efficiency remains unchanged after an insert swap, maintaining stable cycle times.

-

Independent Venting and Ejection System: The venting channels and ejector pin layout on the insert are perfectly matched to its forming area and precisely interface with the ejector plates and venting paths in the mold base, preventing air traps or unbalanced ejection issues due to changes.

3. Standardization and Mistake-Proofing (Poka-Yoke) Design

All interchangeable inserts adhere to strict standardized design specifications, including interface dimensions, cooling/hydraulic coupling specifications, and lifting hole positions. Furthermore, physical mistake-proofing (e.g., asymmetrical locating pins) and electronic identification (e.g., embedded RFID chips) are employed to prevent operators from installing the wrong insert during fast changeovers, ensuring production safety and product consistency.

III. Manufacturing Process: System Synergy Built on Precision

The manufacturing process for such molds is more complex, emphasizing overall coordination and stepwise verification.

-

Systematic Concurrent Engineering: The design of the main mold body and all sets of interchangeable inserts proceeds simultaneously, ensuring part compatibility through a shared coordinate reference system. Manufacturing also adopts a parallel mode, where the main frame and multiple insert sets are machined concurrently, significantly reducing total lead time.

-

Datums First & Match-Machining: The ultimate finish machining of all locating interfaces on the main mold body is completed first, establishing it as the "master datum origin" for the entire system. Subsequently, each insert set is match-machined against this master datum, ensuring all inserts share a "common language," which is the prerequisite for interchangeability.

-

Phased Assembly & Functional Testing: The main mold body (without inserts) is first assembled and its basic functions tested. Then, each insert set undergoes pre-assembly and individual testing to verify its cooling, ejection, and other functions. Finally, final assembly and integration testing are performed. Trial runs are conducted with a specific insert combination, followed by verification of product accuracy and performance after swapping to another insert set.

IV. Core Advantages and Application Value

The value of interchangeable insert molds is realized at every stage of the product lifecycle.

-

For Manufacturers (Mold Users):

-

Reduces Total Cost of Ownership: The cost of one main mold body is significantly lower than developing multiple complete molds. For example, a mold capable of 3 backrest and 2 armrest variants typically represents only 40%-60% of the total investment required for 5 separate, dedicated molds.

-

Accelerates Market Response: Developing a new product variant simplifies to designing and manufacturing a new insert set, slashing the timeline from months to weeks.

-

Improves Equipment Utilization (OEE): Eliminates the need for frequent, complete teardown and setup of large molds. Product changeovers are achieved by swapping inserts on the same injection molding machine, reducing downtime.

-

Mitigates Inventory Risk: Enables flexible, on-demand production based on a "platform mold, family of products" strategy, avoiding the idle asset risk associated with single-product molds.

-

-

For Mold Makers:

-

Represents a concentrated display of technical capability, demanding higher design complexity and machining precision.

-

Fosters long-term, strategic partnerships with clients, transitioning from being a single-mold supplier to a manufacturing solutions partner.

-

V. Typical Application Scenarios

-

Office Chair Series: With a constant base seat, a full product range from basic to premium is created by swapping armrest inserts (full, half, none) and backrest inserts (different heights, lumbar support shapes, mesh patterns).

-

Outdoor/Patio Chair Series: Using the same main frame, different comfort levels and aesthetic looks (flat, contoured, massage-nodule surfaces) are achieved by exchanging seat and backrest inserts.

-

Stacking Chairs (Cafeteria/Conference): While maintaining uniform stackability dimensions, different brand logos or design lines (simple vs. intricate) are achieved on the chair back via interchangeable inserts, meeting the need for branded variation within uniformity for clients like hotel chains or schools.

Conclusion

The interchangeable insert chair mold is far more than a simple structural innovation; it is a profound revolution in manufacturing philosophy. It merges the efficiency of mass production with the flexibility of customization. Through significant upfront investment in sophisticated systems engineering design and manufacturing, it delivers unparalleled agility and economy throughout the entire product lifecycle.

In an increasingly competitive consumer market with rapidly shifting demands, possessing such a flexible manufacturing system equips a brand with a core strategic weapon: the ability to quickly capture niche markets, lower the cost of experimentation, and maximize asset utility. It is not merely a tool for producing a plastic chair but a strategic manufacturing platform that underpins continuous innovation for an entire product family, and even a brand. As digital design, precision machining, and smart identification technologies further converge, this modular mold concept is guiding the plastics processing industry toward a more efficient and agile future.